An organization comprised of six students, founded in Purdue Polytechnic’s digital enterprise systems major, is teaching several Purdue engineering clubs how to use product lifecycle management systems (or a PLM).

The starting point for this organization came when Travis Fuerst, a professor in engineering technology specializing in digital enterprise systems, was approached by a student-run club that had a particularly messy system for keeping track of computer-aided design (CAD) files and other documents critical to their builds.

“You see this a lot, even in real-world businesses,” Fuerst said. “People end up resorting to throwing files into something like Google Drive, and then they aren’t especially useful or transferable to different software.”

So Fuerst helped them transition to using ARAS, a product data management software that is a critical component of the PLM process for many businesses, including Microsoft/Xbox, the Department of Defense, Virginia’s SAIC and others.

Newfound popularity

Next semester, when Fuerst suddenly had a whole host of clubs clamoring to learn these systems, it became too much for one person to handle. That’s when he recruited some of his students in digital enterprise systems to establish an organization that could manage all of the student clubs that wanted to run their projects off of ARAS.

“We have seven clubs currently on board with us,” said John Koellisch, one of the founding members Fuerst recruited for the new organization, and a senior in Purdue Polytechnic’s digital enterprise systems program. “Their membership ranges from anywhere around 15 to 150 students per club—in total we’ve probably worked with around 300 students so far.”

How ARAS benefits Purdue's engineering clubs

Fuerst and Koellisch have identified several ways that learning PLMs can help Purdue’s student-run engineering clubs, whether it’s the rocketry club that Koellisch recently brought on board, to rover or battle-bot clubs.

“Now there’s all this information-sharing between clubs,” Fuerst said. “They can share data, CAD models, they can help each other streamline production processes. It’s way better than being left with hard-to-use files that no one has touched.”

“Another big thing is that clubs aren’t going to have to fight to keep their data intact,” Koellisch added. “There are so many engineering-based student orgs where the new president takes over and goes, ‘Oh, I don’t have our files anymore, because so-and-so graduated and now we can’t get on the shared data drive.’ We can manage that process much more productively for them.”

A steady stream of student groups have continued approaching Koellisch and his peers asking to join this network—a large enough number to justify expanding the group with new members that either have preexisting PLM expertise or who have worked with ARAS after adopting it in recent months. Koellisch thinks that “around 14” people have definitely showed interest in joining, but with a capacity to grow to nearly 50 members if interest persists.

Institutional support

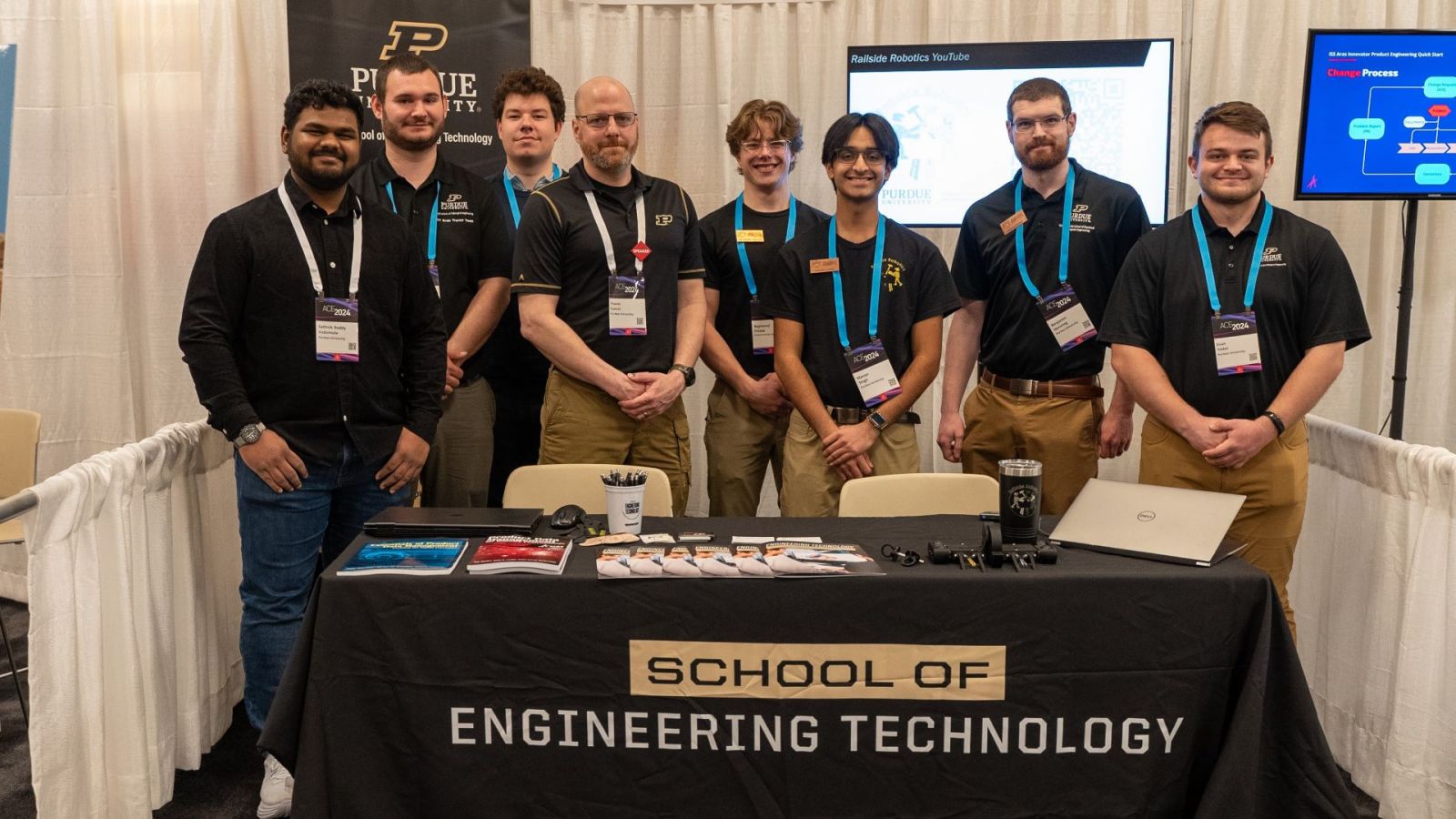

“ARAS has been really amazing throughout this process,” Fuerst said. “ARAS themselves and one of their partners, Razorleaf, have financially supported this group—they actually funded the trip for them to go to Fort Worth and present at their 2024 conference called ACE.”

The company’s interest may stem from the fact that Koellisch and his peers have dealt with many conditions present in real-world industries when companies transfer to a PLM.

“These students go through the same pain-points that you see in new tech adoption at the industry level,” Fuerst stated. “‘Why do we have to use this? Can’t we use an old system we already know?’ And they’ve done a great job at not just explaining, but showing why it makes more sense to use a PLM.”

“This system basically replicates how it works in industry. If you’re using a certain part, you can’t just unilaterally go in and change that part’s design, because you’re now on a server with six other clubs who should have some say in that. So, just like in real life, they have to go through tests and then hold a vote to actually determine whether or not they can make that change. It’s not just a willy-nilly decision anymore.”

The group's future

Koellisch explained that clubs from “pretty much every major you can think of” have expressed interest. “We’re acting as the PLM manager for clubs in the Polytechnic and the College of Engineering, and I think it’ll get even more collaborative. We’ve really become a kind of central mothership where people are coming to us for tutorials on ARAS and how to use this kind of software more widely.”

As Koellisch is a senior, his goal is to find proteges to help advance the organization after he goes into either the workforce or graduate school. In the meantime, Fuerst stated that he will continue working to “establish new partnerships” with various product data management software producers, to incorporate a variety of new digital programs into this student-run support network.

Additional information