.jpg) Written by Amanda Delio

Written by Amanda Delio

A new lab opened in the Computer Graphics Technology (CGT) Department called the Design and Engineering Making Lab. Professor Liang He had many ideas for the lab over the summer while stuck in China for a month. That’s how opportunity arose for him to give a lecture about his PhD work to Tsinghua, Zhejiang, and Duke Kunshan University. He said, “Seeing how other university’s mentor and conduct research has given me ideas about the infrastructure for this lab.” Every place He traveled had different students with different styles of work. Diversity within the fields led to different questions for his own work agenda.

Professor He works in the newly constructed lab with students from his spring semester course. As they continued working together through the summer while traveling, they proposed ideas for the course and progressed in ongoing research projects. His students have also pursued publications over the summer. In the summer the students converted two course projects into poster paper submissions to ASSETS 2023, the top-tier conference on accessibility.

One group of students are working on a tangible tool for people with ADHD. It is squeezable toy, used to capture data on how people interact with the device to give some indication of their mental state and behaviors. Next steps are to develop and build a prototype to run more studies on participants. The students in this group wrote and submitted a paper to ASSETS 2023. It received high scores, but just missed the threshold to make it in. They have reconvened to work on another publication to submit to a different venue in January of next year.

Two of He’s students from India wanted to understand how to measure needs, challenges, and opportunities among India’s caregivers. Receiving a chance to interview caregivers and family members of mostly dementia patients gave a real sense of the challenges this community faces. They were able to recognize what technologies would help support them. Through this study the research was used to write another publication and they will present at ASSETS 2023 this October.

Professor He says he hasn’t mentored students remotely before, and that the main challenge is to figure out how research can be properly conducted in this setting. He is interested in resolving this challenge and he feels that his team has done well thus far. He hopes to mentor more students from other campuses in the future.

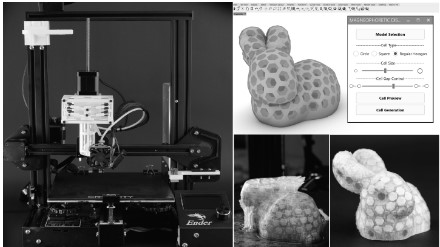

Professor He’s PhD work is in 3D printing digital fabrication. He has worked on converting 3D printed objects into interactive items. His approach uses all kinds of 3D-printed springs. To understand how the 3D-printed spring performs, He uses mechanical engineering techniques like torsion testing to find information on torsional shear stress, maximum torque, and breaking angle of the material. He then develops a software design tool with several plugins and a user to embed those springs in the 3D model.

The springs can be made to bend, deform, conform, or comprise. Electronics can also be added to make the object interactive and react to the user’s input. He has come up with different software variations for the end user to interact with these springs.

He also received a grant from Purdue Polytechnic’s Holistic Safety and Security Research (HSS) for robotics. The question the grant sought to answer was: how do people with disabilities perform tasks in their daily life?

For example, how do blind people navigate through a building? How do they cross the road with or without certain aids? Or, for those with hearing impairments: How do they focus on others in a group discussion? How does a speaker catch their attention? These are experiences of disabled people that the researchers seek to understand better. After understanding, they want to create robotic solutions to help them.

For a blind user’s navigation challenges, robots can be attached to the body and provide haptic feedback to indicate where to turn, and where to stop. Ideally, they would like to create a set of robots that are wearable and moveable on the body to provide aid for many different tasks and disabilities.

One student is working on the first interface which enumerates the tasks and solutions the body can support. They hope to find results to report to publications in November. After that, they will then transition to making the robots.

In early November at UIST 2023 a San Francisco conference, researchers will discuss a 3D printer display inspired by Etch A Sketch. The goal is to have a tool that can create any kind of shape with a display so users can annotate and sketch various geometric shapes as 3D models.

In early November at UIST 2023 a San Francisco conference, researchers will discuss a 3D printer display inspired by Etch A Sketch. The goal is to have a tool that can create any kind of shape with a display so users can annotate and sketch various geometric shapes as 3D models.

Current use-cases implement the shape of a rabbit. Users can convert the whole body into a magnetophoretic display, then use the magnetic pen to draw any patterns on the body and even erase it from the inside. Each cell inside the bunny has a mixture of low-efficiency liquid that allows magnetic particles to stay in one spot inside the cell. Printing this model is very challenging. The 3D printing nozzle is modified by installing a syringe to shoot the powder and liquid base in a program. They also have developed software for the end user specifying what shape can be converted into the display shape. The software will also customize the shape of the object, the cell shape and cell premises.

There has also been exploration in other directions, like how 3D printing can support sustainability in agriculture. He and his students are experimenting with creating 3D-printable living plants. They have tried cat grass and chia seeds using the 3D printing process. They then control the growth of the plant by controlling light and humidity, wind and temperature.

The current question is whether the printer can be modified to implement the print and deposit the seed, give them water and show the shape, lights and external controls to customize the seed and make different prints. He’s vision is to start from a very small hand-sized scale, to room- then building- then city scale. He says, “Working with living animals and plants is interesting. Everyone likes plants.” He and his students will continue to explore possibilities for technology to support or connect nature and human beings to see what can be augmented and facilitated using technology.

Combining all these directions Professor He has an umbrella term: Context Aware Fabrication and Experience. Digital fabrication can be an effective way to approach, understand and interact with environments. It is a tool for them to perceive the environment and both the natural and digital world. He hopes in the next few years all these projects will bear important results.

Professor He also urges his students to work on different things and find an interest and passion aimed at productive careers. He has some ideas but doesn’t attempt to push the students to do what he wants to do. Professor He says he is not the driving force for the new research lab; they are. His responsibility is to guide them to what they are passionate about. Then he can then give them experience, feedback or tips on how to seek out their own goals. His hope is to create a space where the students feel comfortable, and he can work with students which is what he loves to do.

For more information, please visit Professor He’s lab webpage: www.de4m.xyz.

Written by: Amanda Delio