Attention to detail is critical when designing components for equipment and reverse engineering existing ones. Oftentimes, the detail required is far smaller than can be noticed by the human eye but which could be catastrophic if left unnoticed.

Rosemary Astheimer, assistant professor of practice in computer graphics technology, understands the importance of precision. She teaches courses in the virtual product integration major that focus on 3D CAD (computer-aided design) modeling and how that technology is used in product lifecycle management. She says it is vital to capture detailed requirements when designing.

Rosemary Astheimer, assistant professor of practice in computer graphics technology, understands the importance of precision. She teaches courses in the virtual product integration major that focus on 3D CAD (computer-aided design) modeling and how that technology is used in product lifecycle management. She says it is vital to capture detailed requirements when designing.

“My classes teach students how to build 3D models that not only display the products themselves but also explain how they’re manufactured, how they’re inspected and how they’re serviced,” said Astheimer. “The data captured in CAD is reused throughout the product’s lifecycle as traditional manual industry practices are transforming to become automated through machine-to-machine communication.”

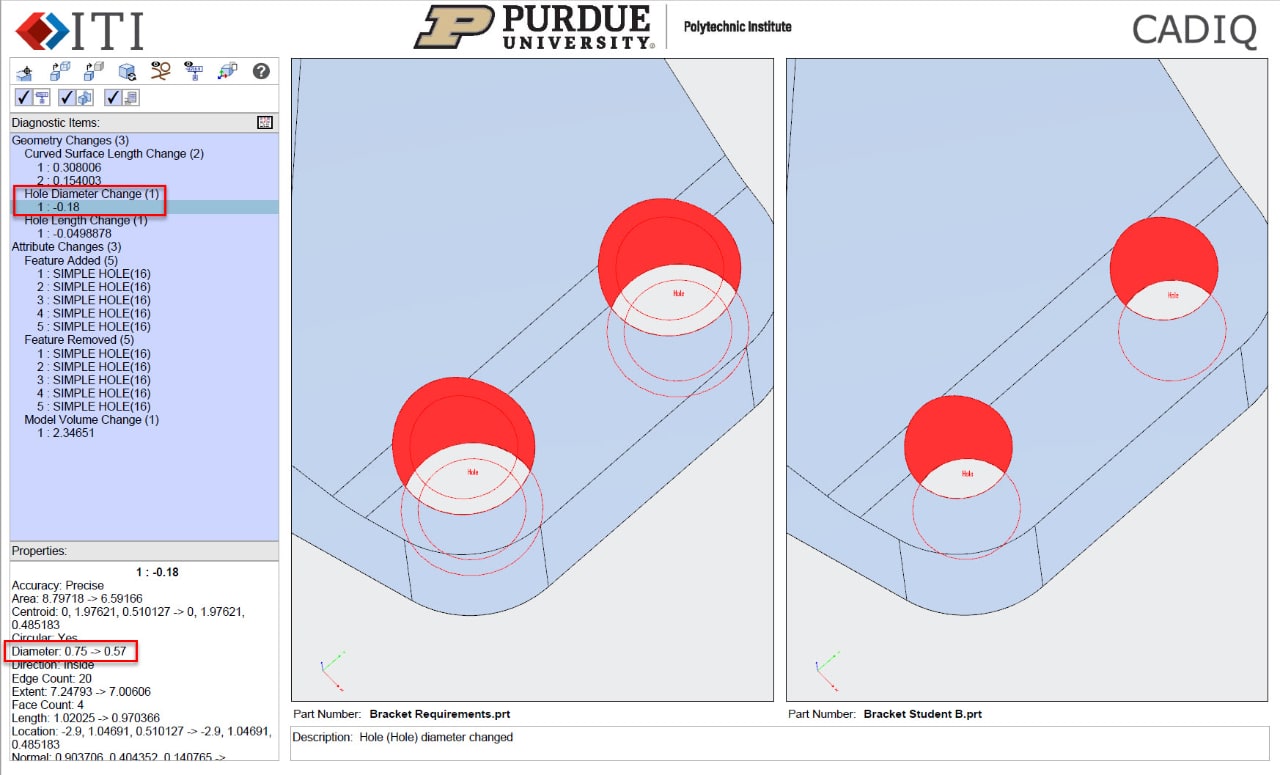

Students in Astheimer’s courses receive feedback on their work in the form of documents generated by CADIQ, an innovative CAD software that identifies differences in the 3D product models that students create compared to the models they were assigned to replicate. CADIQ highlights those modifications and discrepancies via an interactive, side-by-side 3D PDF document that can be toggled and zoomed in to show product detail.

“This allows you to compare and verify that the product geometry is the same,” said Astheimer. “It illustrates subtle differences in a product’s geometry that can have an effect on important details, such as the item’s center of gravity or even differences in volume, which will drive the weight of the product.

“When you create a 3D model of a component, you often need to translate the data into a neutral format that other systems can read for manufacturing or inspection. CADIQ can compare the translated data and verify if and how something has changed from the original piece unknowingly,” Astheimer said. “That’s a standard industry practice, which is why it makes it a good experience for my students.”

"Having access to industry documentation helps students become familiar with the various ways companies use data visualization,” said Samantha Kovats, a junior majoring in virtual product integration. “Seeing this type of variability not only helps to better prepare students to transition into the workforce, but also improves our ability to succeed as students. The 3D PDF generated by CADIQ, in particular, gave me a much better understanding of my part and its specific features that needed improvement, something that was a lot more difficult to do in previous labs without this information."

“I found that the 3D PDF generated by the CADIQ software made it much easier for me to understand what I did wrong on the assignment and what I needed to do to fix it,” said Jake Donovan, senior in web programming and design/virtual product integration. “The document also helped me better understand the results and my grade for the lab.”

Astheimer uses CADIQ in her CGT 20301 (Model-Based Definition) course and plans to use it this fall in CGT 10301 (Geometric Modeling Applications). She recommends the software to any student who plans to go into careers that involve product design, quality assurance and product inspection.

“Even someone who isn’t a product designer will need to know how to communicate design specifications between stakeholders,” she said. “I want my students to have an experience that mimics industry practices. That is my goal.”

Additional information

- Product lifecycle students use new software to optimize their product designs

- New book from CGT professor explores model-based definition