For her students in Purdue Polytechnic’s Department of Computer Graphics Technology, Rosemary Astheimer found the real-world challenge for their class assignment right on Purdue’s campus.

Astheimer, assistant professor of practice, asked Purdue’s Society of Automotive Engineers (Purdue SAE) team if her students could help improve their vehicles in any way. Three SAE teams (baja, combustion engine and electric powered) provided the students enrolled in her spring semester course, CGT 32600 (Graphics Standards for Product Definition) with specifications of automotive parts in the vehicles they design and build. The challenge she gave her students was to find ways to improve the design of those components.

Astheimer, assistant professor of practice, asked Purdue’s Society of Automotive Engineers (Purdue SAE) team if her students could help improve their vehicles in any way. Three SAE teams (baja, combustion engine and electric powered) provided the students enrolled in her spring semester course, CGT 32600 (Graphics Standards for Product Definition) with specifications of automotive parts in the vehicles they design and build. The challenge she gave her students was to find ways to improve the design of those components.

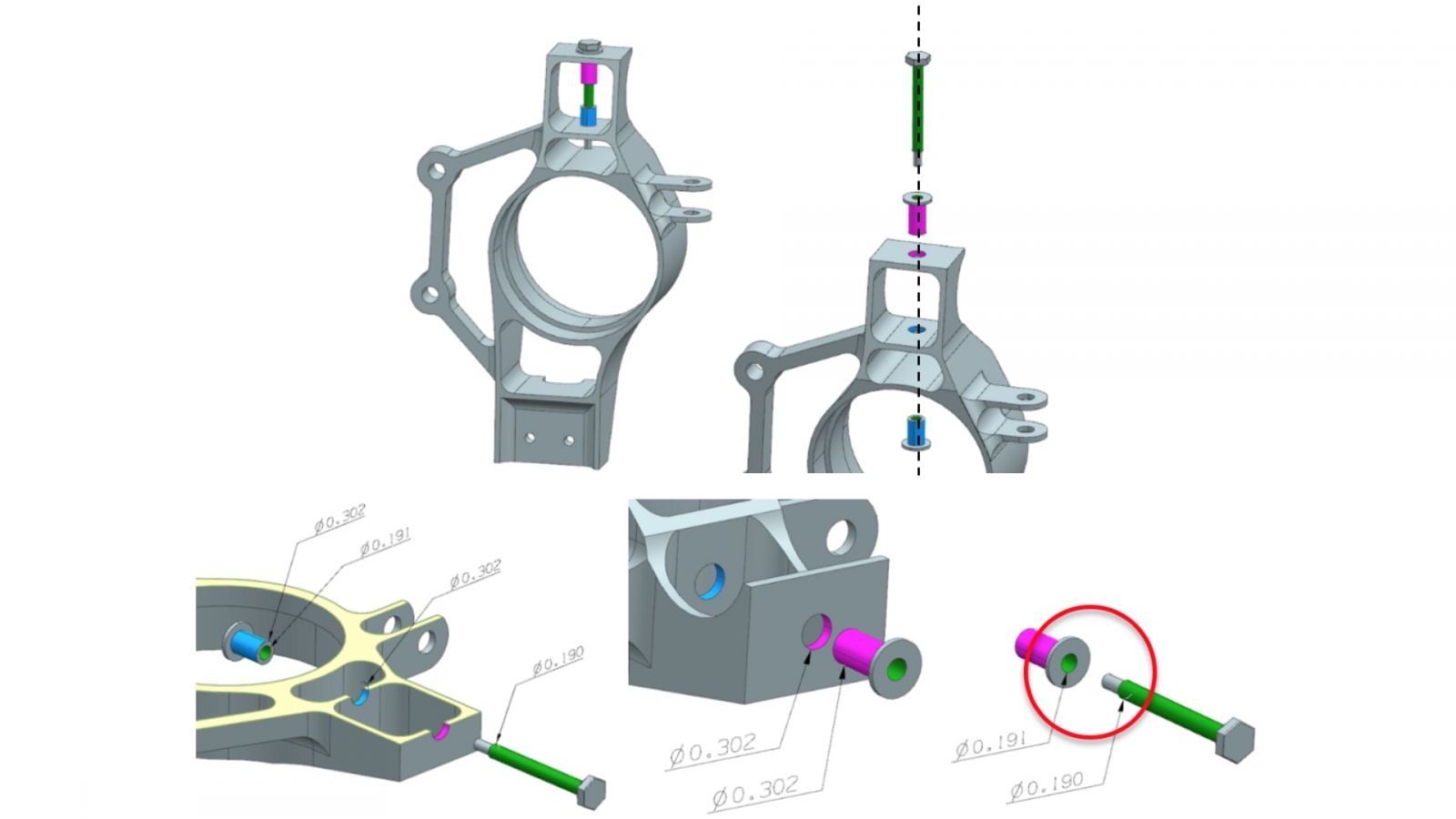

Students in one section, for example, analyzed the SAE team’s design for a part in their vehicle’s front upright assembly, an integral portion of its suspension system. The part helps connect the vehicle’s control arms, steering arms, springs, shock absorbers, brakes and tires.

Armando Good, William Stahlschmidt and Alexis Tran, who comprised one team, determined that using aluminum alloy 6061-T6 to manufacture the load-bearing upright would result in a 35% reduction in cost and slightly reduced weight. The 7075-T7 alloy specified in Purdue SAE’s original design is widely used for highly stressed components, the team said, but alloy 6061-T6 retains a stress tolerance that is ten times the maximum needed for the part. Changing alloys would cost less to manufacture and more than satisfy safety requirements, they said.

Ethan Iglehart and Karol Blasinski researched improved geometric dimensioning and tolerancing rules for the component, allowing for better fits between its parts. They performed a stress analysis, determining that it could be reshaped in places to save weight while retaining strength.

Other teams suggested better-sized connecting parts and/or changes to the front upright assembly’s design for better fit with existing connecting parts, among other potential design improvements.

Besides teaching product design, Astheimer stresses the importance of time management with her students.

“I encourage students to set deadlines and milestones throughout the semester,” Astheimer said. “It’s helpful to know where you are and what time you have left to complete the work.”

Understanding the Principles of Product Lifecycle Management

Students in Astheimer’s CGT 20301 (Model-Based Definition) course paired up with students from CGT 10301 (Geometric Modeling Applications), and worked together to illustrate how the manufacturing industry benefits from the use of 3D constraint-based modeling, which ensures the standardization of products and enables communication about those products between a company’s departments. She provides case studies and asks students to explain the concepts of a “digital twin” and “digital thread.”

Erik Cedarquist, Spencer Hale and Kai Mangiaracina, a student team, referred to a digital twin as a “digital representation of a product that defines its components, materials, geometry, behavior and intent.” Alterations can be made to a digital twin without incurring high production costs that would result from changing specifications of an actual product.

Another team, Logan Gauker, McKenzie Landorf and Nicole Limade, explained the concept of the “digital thread” as the link of communication that connects product data to different departments within an organization, such as engineering and marketing.

“Through the use of the Internet, the digital thread has exponentially increased in versatility,” said Gauker. “It allows for sharing of information to reduce errors and save money.”

Each student team documented their design process and created narrated presentations to summarize their research. Providing feedback to each team is an important part of Astheimer’s instruction, both to evaluate the results of their work and to give them useful tips for future design projects.

One team, for example, included a diagram showing both the original design of the component and their improved version.

“It’s good that you included the before/after comparison,” Astheimer noted in her feedback. “Otherwise, the reader who is not as familiar as you were with the part might have a hard time spotting the differences.”

Additional reporting by Brigid O'Brien.

Additional information:

To learn more about the computing and graphics subject areas at Purdue Polytechnic, visit polytechnic.purdue.edu/find-your-major#computing-and-graphics.