The School of Engineering Technology will hold an open house to demonstrate industry-supported renovations in two Knoy Hall labs this Friday, May 8.

The School of Engineering Technology will hold an open house to demonstrate industry-supported renovations in two Knoy Hall labs this Friday, May 8.

As a yearlong senior capstone project, students in MFET 48000 (Project Planning for Integration) collaborated with industry partners to design and build the Purdue Integrated Process Educational System (PIPES) in the Automated Manufacturing Center, Knoy 258.

“The manufacturing engineering technology seniors have been working to complete the project and make the system fully operational,” said Brad Harriger, professor of manufacturing engineering technology.

Harriger and Grant Richards, clinical assistant professor of electrical engineering technology, along with other faculty, plan to integrate the new system into project-based curricula. The lab’s equipment and software will serve as key educational tools to teach applied process and continuous control, primarily from technology and implementation perspectives.

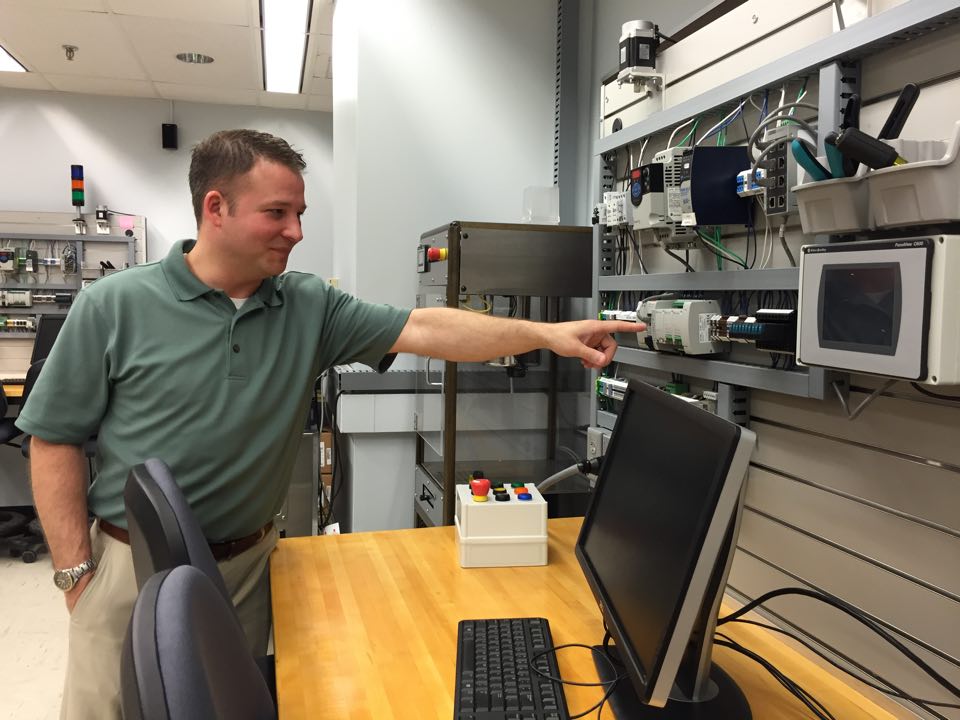

In the industrial controls lab in Knoy 102, new programmable logic controllers (PLCs), human machine interfaces (HMIs), and variable frequency drives (VFDs) have been installed.

In the industrial controls lab in Knoy 102, new programmable logic controllers (PLCs), human machine interfaces (HMIs), and variable frequency drives (VFDs) have been installed.

“The gifts allow for the integration and expansion of our industrial control laboratory courses,” Richards said. “We now have the capacity to introduce more students to industrial automation than before.”

The renovations for both labs were completed with the support of Rockwell Automation, Endress+Hauser, Kirby Risk, GE Booth, Hoffman Enclosures, and BMW Constructors. Gifts included process management instrumentation, 70-gallon tanks, control panels, piping, pumps, valves, and other hardware and engineering services.

The renovated labs will also lead to new opportunities for collaboration with industry partners.

“In a year or two, we can see this equipment being used for workshops marketed to industry, where practicing engineers would come to Purdue for several days to learn about and experience process control integration,” Harriger said. Workshops would be jointly taught by faculty and industry representatives.

Through their senior capstone projects, engineering technology students already work directly with industry sponsors, visiting their factories and building solutions for their sponsors’ real-world problems. Workshops in these labs will provide more opportunities for practicing engineers to visit Purdue.

“It’s a natural fit,” said Ken Burbank, head of the School of Engineering Technology. “Workshops held here in our state-of-the-art labs will provide new opportunities for people from industry to work with our faculty and students. The learning goes in both directions. We will all benefit.”

Don Cummings, technical talent manager at Endress+Hauser, agreed.

“We know that many students don’t know about the process industries that we serve, nor the industry that serves them,” he said. “The collaborative project aspect of working together [in these labs] will set an example for creative problem solving, exposing students to our people and a culture of mutual achievement.”

Additional info:

Launch of renovated manufacturing lab at 2:30 PM on Friday, May 8