Rosemary Astheimer challenges CGT 22600 (Introduction to Constraint-Based Modeling) students with a different project every semester, and Rotor Clip’s “Ring-A-Majig” contest provided the inspiration for this spring’s coursework.

In the course, students focus on learning how to use Computer Aided Design (CAD) software and then applying what they’ve learned to create product designs and build prototypes of those designs which incorporate 3-D printed and laser-cut parts.

“I like students to experience the challenges they will face when working in industry, including working in groups, coming up with designs that fit the requirements given to them, and then getting firsthand experience manufacturing their products,” said Astheimer, continuing lecturer in computer graphics technology.

“I like students to experience the challenges they will face when working in industry, including working in groups, coming up with designs that fit the requirements given to them, and then getting firsthand experience manufacturing their products,” said Astheimer, continuing lecturer in computer graphics technology.

Rotor Clip, a Somerset, New Jersey-based manufacturer of retaining rings, wave springs, hose clamps, and other parts used in the automotive, aerospace, wind power, and other industries, sponsors the “Ring-A-Majig” contest for students in technology programs to demonstrate how the company’s retaining rings and wave springs can be used as alternatives to other fasteners and coil springs. Astheimer worked with Rotor Clip’s Jürgen Wenzel, marketing communications manager, and Joe Cappello, global marketing director, to obtain CAD models of the rings and actual parts to be incorporated into student prototypes submitted for the contest.

“I love the idea of having students work on a real project,” said Astheimer. “In this case, the contest pays money for the best designs. What more could a college student want?”

Students routinely discover that 3-D-printed parts and laser-cut parts are manufactured with different levels of accuracy.

Students routinely discover that 3-D-printed parts and laser-cut parts are manufactured with different levels of accuracy.

“When you put parts together which were manufactured using different methods, they don’t always work well together,” said Astheimer. “It’s referred to as tolerancing. Students must learn to adjust for it in their CAD models during the design phase.”

Prototypes from several teams were accepted into Rotor Clip’s contest, and two of those were selected as the final top five entries.

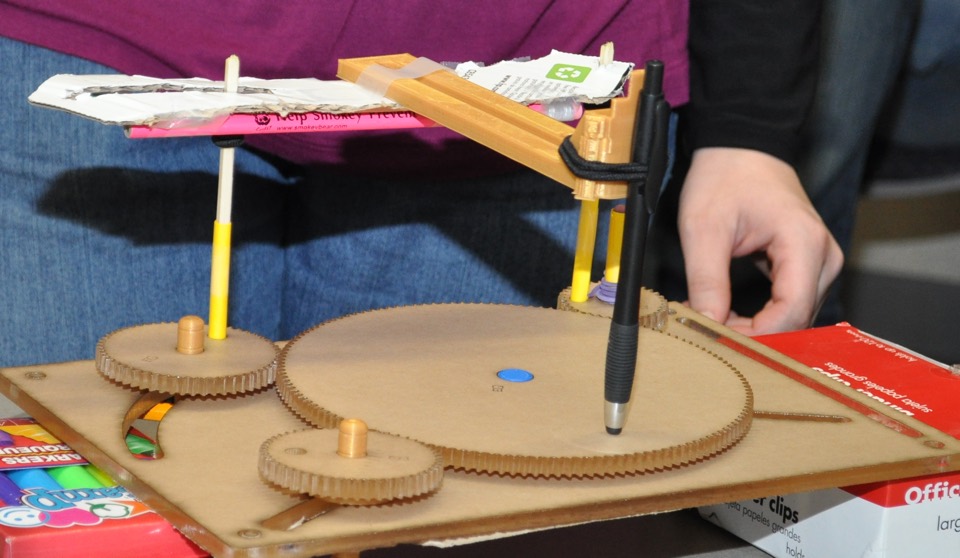

Paul Gemperlein, Emily Maneke, Jake Piekarski, and Lexie Ritter, members of the “Equinox” team, built a Spirograph, a cyclical drawing machine, which features four interchangeable gears, a slotted base, and a pen carriage. Hand-powered gears rotate the drawing surface and pen location to create cyclical patterns.

Jake Austerman, Chris Herr, Collin Nguyen, and Kade Venters, members of the “T1” team, built a model car that drives itself forward using the power of its embedded wave spring.

Update (May 11, 2017):

Rotor Clip announced that the Spirograph project built by Paul Gemperlein, Emily Maneke, Jake Piekarski, and Lexie Ritter won second place in the Ring-A-Majig contest.