At Howmet Aerospace's LaPorte, Indiana facility, a ZEISS ScanBox is used to inspect manufactured parts for defects. The ScanBox, which has been donated to Purdue by Howmet, is an industrial 3D scanner that creates a digital twin of the manufactured part and compares it to its nominal counterpart. Team 29 has been tasked with the following:

1. Design a fixture to hold the Howmet part that optimizes the quality of the scan while keeping part-to-part scan time below 50 minutes.

2. Using the ZEISS Inspect software, develop a scanning path and script that minimizes the amount of interaction needed from the ScanBox operator, while producing a go or no-go report.

3. Create a processing algorithm or function in external data manipulation software (e.g. Excel, PowerBI, etc.) that the engineers can use to debug areas of defect on parts.

Semester of Project:

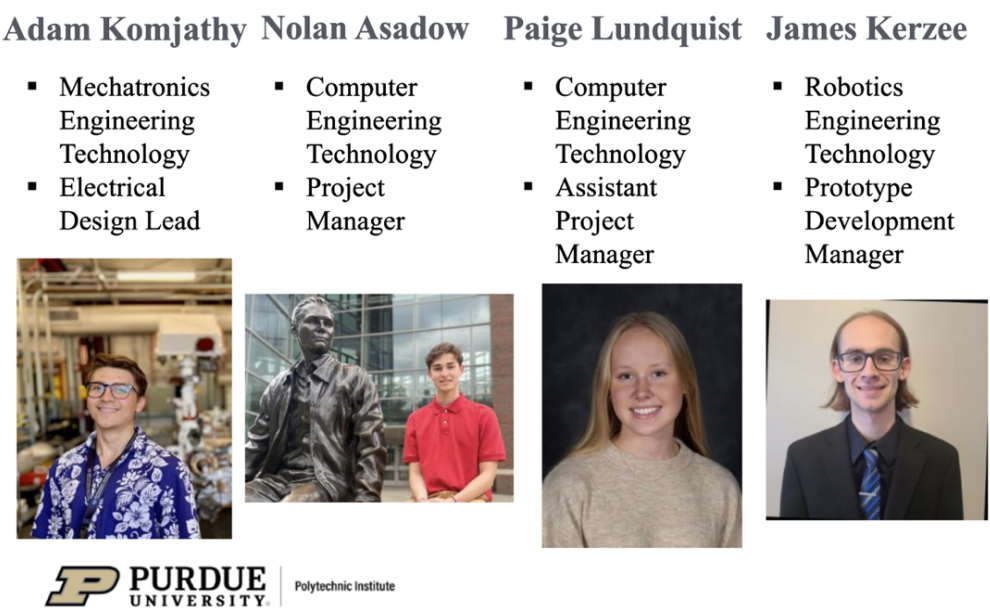

Team Photo: