Research Projects Follows RDD&D Approach

Areas

•Machine Drive Systems for Hub Motors

•Ultra Capacitor integration for Extended Battery Life and High Peak Current Delivery

•Grid Tied Inverters for Smart Grid

Machine Drive Systems

When electric vehicles are driven by hub motors, power electronics controllers must work with stability controllers. This project includes a dSpace based controller development, power electronics hardware for BLDC hub motors, and controller modeling. A novel motor fault detection mehod and traction control algorithms are developed and tested on a actual system. A Ph.D. dissertation and several publications were produced from this project. Collaborators include Purdue ME department faculty.

-

Traction Control

-

Electronic differential

-

Motor fault detection

.png)

.png)

Publications and Intellectual Property

Kuruppu S.S., Kulatunga, N.A., “D-Q Current Signature based Single Winding Open Fault Detection for SM-PMAC Machine Drives”. IEEE IEMDC 2013 Chicago, IL.

Kuruppu S.S., Kulatunga, N.A., “D-Q Current Signature Based Faulted Phase Identification for SM-PMAC Machine Drives”, Industrial Electronics IEEE Transactions on, (in Review)

Kuruppu S.S., Ariyur K. B., Kulatunga N.A., “Electric Machine Extremum Seeking Slip Optimization for ABS”. Vehicular Technology IEEE Transactions on, (in Review)

Open phase fault diagnostics (patent pending)

Electric machine based extremum seeking slip optimization algorithm (patent pending)

Energy Cell

What an Energy-cell?

Energy-cell is an auxiliary energy storage coupled through a power electronic interface for the purpose of assisting the battery of a electric vehicle when required. This a joint project between PEDAL and the Electrical Engineering Department at the University of Darmstadt, Darmstadt, Germany.

What is the importance of an energy cell?

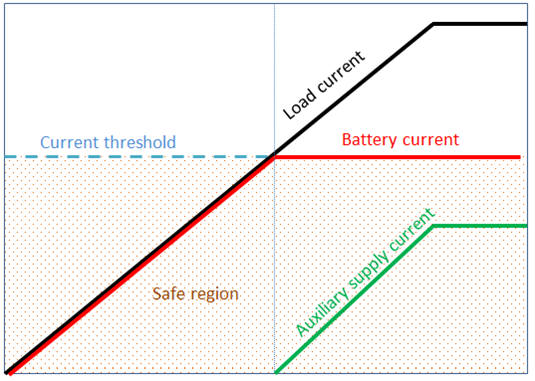

Drawing high currents beyond a certain threshold limit can be harmful for rechargeable batteries.

The life cycle of the battery would diminish when this current threshold is exceeded repetitively.

During high acceleration or start up electric vehicles can draw very high currents that exceeds this threshold level.

Usually such high currents would not last for more than few seconds.

An auxiliary power supply can supply the additional current required to maintain the battery current below its threshold.

The auxiliary power supply should be able to deliver very high currents in a small period of time.

A Power electronic interface is required to regulate the current flow of the auxiliary energy storage.

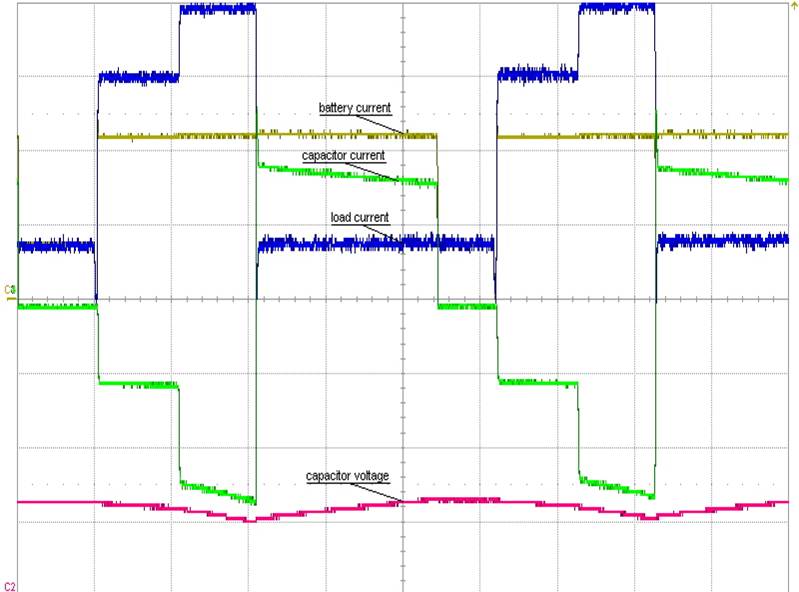

Above figure shows that battery supplies the load current until the current reaches to a threshold value. After that, the battery current is limited to that value and the additional will come from the capacitor. Figure below shows the actual test data where the load is changed in a step manner (blue line). Battery current (yellow line) does not change, However, capacitor current (green line) varies as capacitor discharges to supplement the load current and charges from the battery when for the next demand.