Updated April 9, 2020

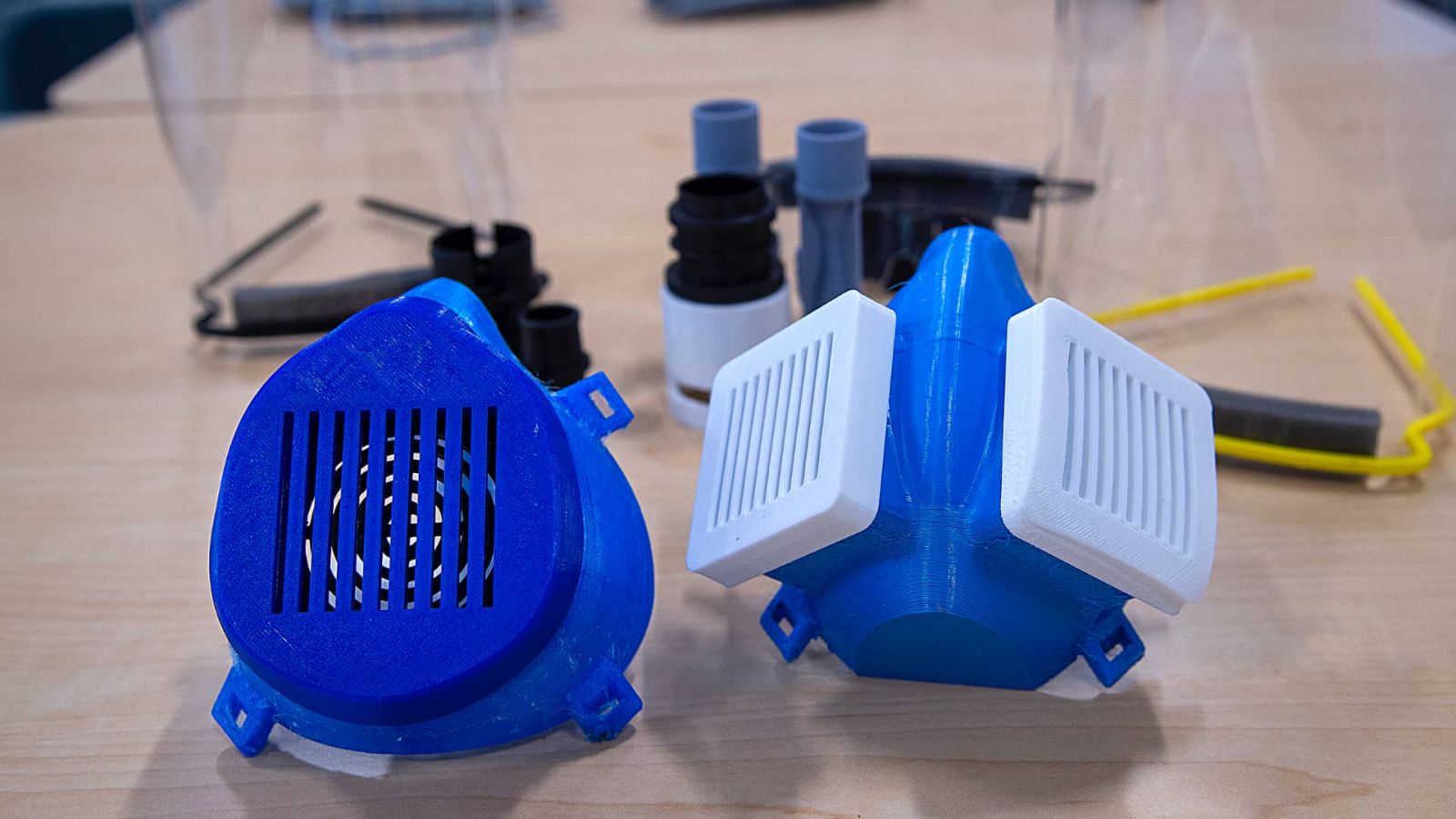

A volunteer group of 40 Purdue faculty and staff are producing medical supplies for Indiana hospitals, including safety glasses and face shields. They’re also developing an improved design for N95 respirators that can be easily disinfected.

Nate Hartman, Dauch Family Professor of Advanced Manufacturing, head of Computer Graphics Technology in Purdue University’s Polytechnic Institute and co-executive director of the Indiana Manufacturing Competitiveness Center (IN-MaC), is leading the effort.

Nate Hartman, Dauch Family Professor of Advanced Manufacturing, head of Computer Graphics Technology in Purdue University’s Polytechnic Institute and co-executive director of the Indiana Manufacturing Competitiveness Center (IN-MaC), is leading the effort.

Makers, the volunteer group, includes faculty and staff from Purdue Polytechnic, the College of Engineering, the College of Pharmacy and the School of Nursing, as well as Birck Nanotechnology Center, Ray W. Herrick Laboratories, the Bechtel Innovation Design Center and the Envision Center for Data Perceptualization. They’re working closely with physicians and staff at IU Health, IU School of Medicine and Franciscan Health.

“Getting this done has been a lesson in persistence,” Hartman said. “Two weeks ago, when a few people began sending each other emails about discussing this, it seemed like it wouldn’t be possible. But people kept getting involved and offering their expertise and equipment. Within a week we began working on a plan, and now we have produced useful PPE (personal protective equipment) for the health care community.”

For routine research and instruction in the fields of manufacturing, technology and engineering, Purdue operates several small manufacturing facilities, with capabilities that include injection molding, vacuum forming, roll-to-roll manufacturing, machining, 3D printing, laser scanning and assembly operations.

“We realized we had the expertise and the capacity to help, so why wouldn’t we?” said Hartman. “It's a fast-moving situation, but our faculty and staff are working together to do as much as they can for the people of our state.”

Weeks earlier, as most students left campus and Purdue moved to remote teaching and learning, some of the labs being used for the project became far less busy than normal. But designing and producing medical supplies for Makers’ project has allowed participants to feel empowered in a difficult situation, according to Davin Huston, assistant professor of practice in the School of Engineering Technology and advisor for the experimental BoilerMAKER Lab in Knoy Hall of Technology.

“Ours is a lab that has never been busier,” Huston told the Lafayette Journal & Courier. “It is something absolutely productive for our country and our state. It actually turned my mind around from being down about all of this (the pandemic), to an opportunity to push and learn new things and figure out how to mass manufacture from my lab.”

Graduate students and staff at Purdue Polytechnic’s Digital Enterprise Center are also participating in the project.

See the full Purdue News article.

Additional information

- Boiler 'Maker' team begins producing medical supplies (Purdue News)

- Coronavirus in Indiana: Purdue labs crank out protective gear for Lafayette hospitals (Lafayette Journal & Courier)