Student teams in Purdue Polytechnic’s School of Engineering Technology will present the results of nearly 40 industry-sponsored senior capstone projects on Friday, April 28, in the Ross Enterprise Center at the Purdue Research Park.

Students worked to design and build their projects throughout the fall and spring semesters. Most projects required teams to improve a process to increase safety, efficiency, or automation for a customer.

Projects which will be demonstrated include:

- An Americans with Disabilities Act-compliant rotating cooktop for people who use wheelchairs.

- Modernized tracking methods to improve efficiency at a forge.

- A zero-touch force gesture recognition system.

- An apparatus for enhancing blood collection through automation.

- A mechanism for pre-loading robotic surgery tools.

- A device for automating the separation of EDM electrodes.

- Thermal monitoring and control of die casting.

- A device for detecting and reporting fuel theft.

- Dorm room furniture with integrated appliances.

- An automated poly-film remover.

- A system for testing electromagnetic interference levels in aircraft.

Industry sponsors include Boeing (Puget Sound, WA), Caterpillar (Lafayette, IN), Fiat Chrysler Automobiles (Kokomo, IN), FirstBuild (Louisville, KY), GE Aviation (Cincinnati, OH), John Deere (Moline, IL), Phlebotics (West Lafayette, IN), Stryker (Kalamazoo, MI), Subaru (Lafayette, IN), Toyota (Columbus, IN), and others.

The senior capstone course is led by Phil Sanger, professor of electrical and computer engineering technology, and Frederick Berry, professor of engineering technology. The course, which originated in 2012 with three student projects, encompasses nearly 40 projects now and will expand to 50 next year.

The senior capstone course is led by Phil Sanger, professor of electrical and computer engineering technology, and Frederick Berry, professor of engineering technology. The course, which originated in 2012 with three student projects, encompasses nearly 40 projects now and will expand to 50 next year.

“We are facilitating a growing number of projects in the capstone course because we want every student to graduate with significant real-world experience,” Sanger said. “Classroom learning is important and creates a necessary foundation, but having hands-on projects with actual industry clients makes our students better prepared for the job market.”

Several projects were international in nature, requiring student teams to work with counterparts in Denmark, Germany, the Netherlands, and Peru.

“Companies sell their products to customers around the world. They also design products which often have components built in several countries,” Sanger said. “Our students learn to solve problems which span continents and cultures.”

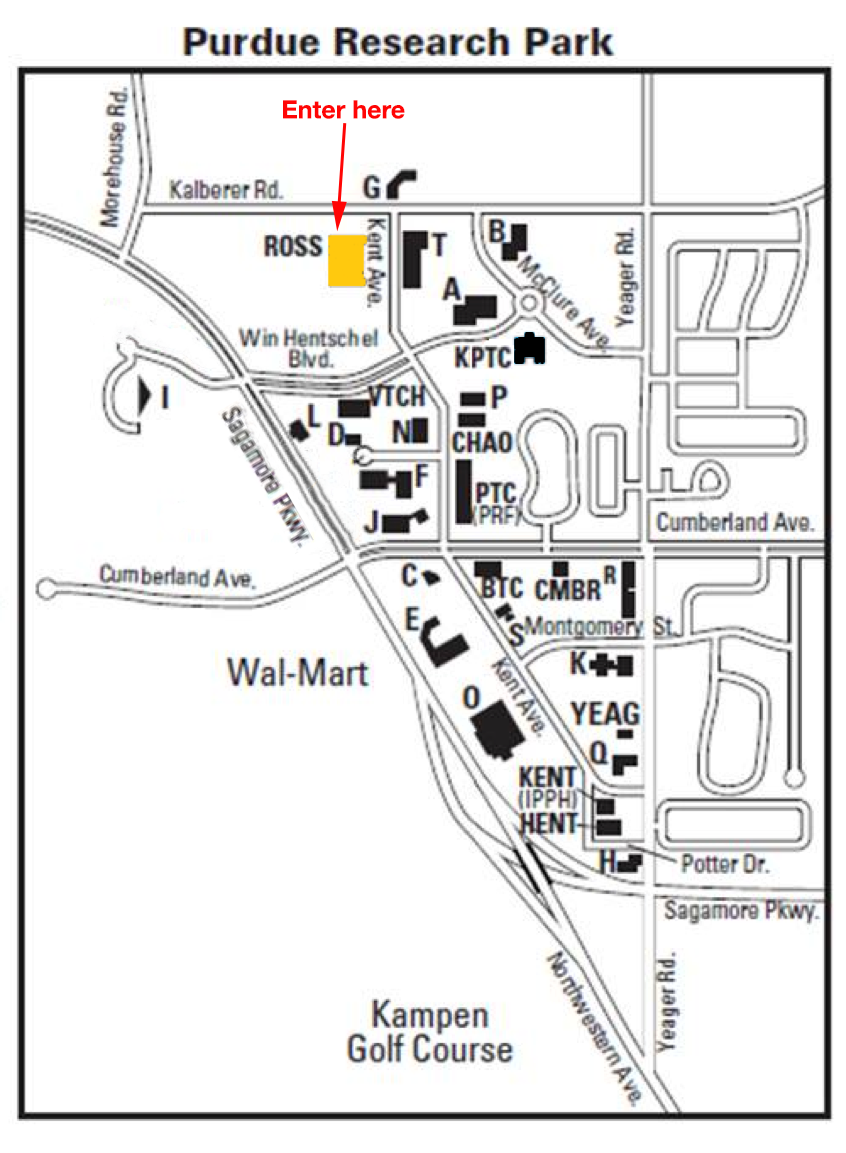

The projects will be on display from 1-4 p.m. Friday, April 28, at the Ross Enterprise Center, 3495 Kent Ave. To find the presentations, park on the north side of the Ross building (adjacent to County Road W 350 N / Kalberer Rd.) and enter via the door toward the right as you approach. Follow the signs inside to find the students' lab.