Purdue Polytechnic, the college for technology at Purdue University, recently hosted the spring 2024 Tech Expo run by the School of Engineering Technology.

Tech Expo is the final showcase for seniors in engineering technology, where they display their capstone projects—an assignment needed for graduation—with a range of projects across engineering disciplines, with goals determined by the remit of the students’ collaborators among faculty and industry sponsors.

This year’s Tech Expo featured 60 projects distributed among approximately 25 sponsors. Student groups and sponsors are matched, along with specific Polytechnic faculty, to projects that will solve a tangible problem for the sponsor.

Last year’s Expo showcased around half the number of projects, thus for 2024 the student teams branched out to a wider breadth of topics and research areas.

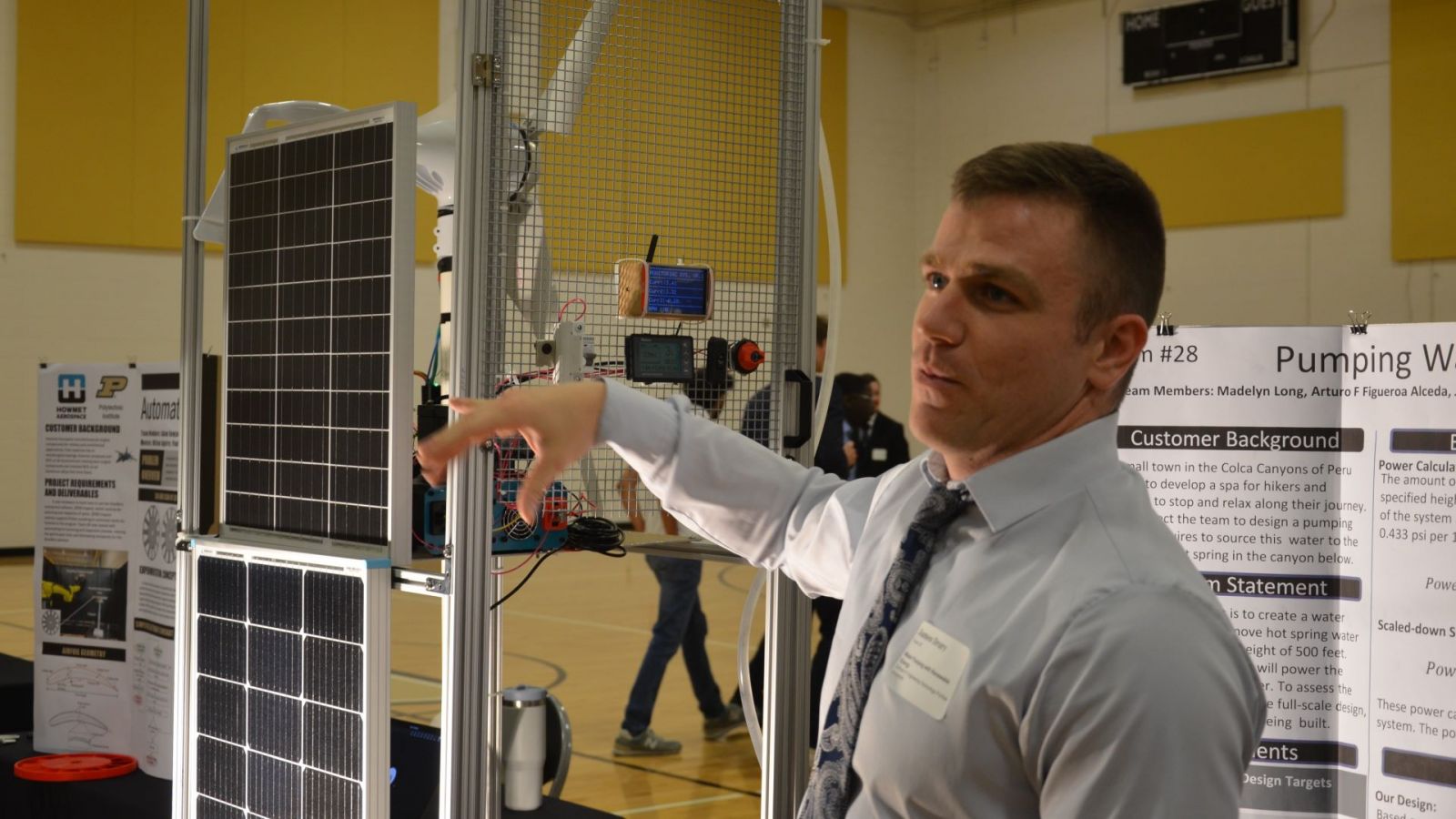

Team 28, for instance, was sponsored by “a small town near the Colca Canyon in Peru,” according to electrical engineering technology senior James Drury.

“The town has this geothermal hot spring, and they wanted an environmentally-conscious way to pump the spring water vertically about 150 meters into a spa,” Drury said. Drury and his six teammates were the first team to work on this project, along with the help of their faculty partner and liaison with the Peruvian crew, Ralph Munguia.

“They wanted hikers journeying through the canyon to be able to stop and relax in a hot tub. … The wind in the mountains can generate about 400 watts, and each individual solar panel can generate an additional 100. The challenge was building our test model to be powerful enough to generate the 1.5 kilowatts we needed to push that water up 150 meters.

“We were able to prove that you can have a self-sustainable system. Because there’s no external output power here, it’s all being run off renewable energy.”

Other teams were involved in continuing projects, picking up where prior teams of seniors had left off. In some cases, such teams had to radically modify what came before in order to update the technology.

“This was a continuing project, but our sponsors at Bechtel [Innovation Design Center] really allowed us to go for it,” said Jacob Creviston, an energy engineering technology major from Team 6. Bechtel provides students with an abundance of tools to work on technology-focused projects, from laser cutting, electronics manufacturing, to 3D printing and more.

“We’ve programmed an electronic measurement tool and an accompanying workstation that allows you to make extremely precise cuts of 80/20-type aluminum,” Creviston said. “Just because of the degree of precision we were looking to get out of the measurement device, we redesigned basically the entire setup from where we picked up this project. And it worked out, because now we have a much more accurate measurement system and a much more portable, usable workstation.”

Several projects focused on overcoming technological barriers that have only become problems in recent times. It is only within the last few years, for example, that research capacity and commercialization in outer space has become a new frontier for many industries. Think asteroid mining or pharmaceutical production, for example.

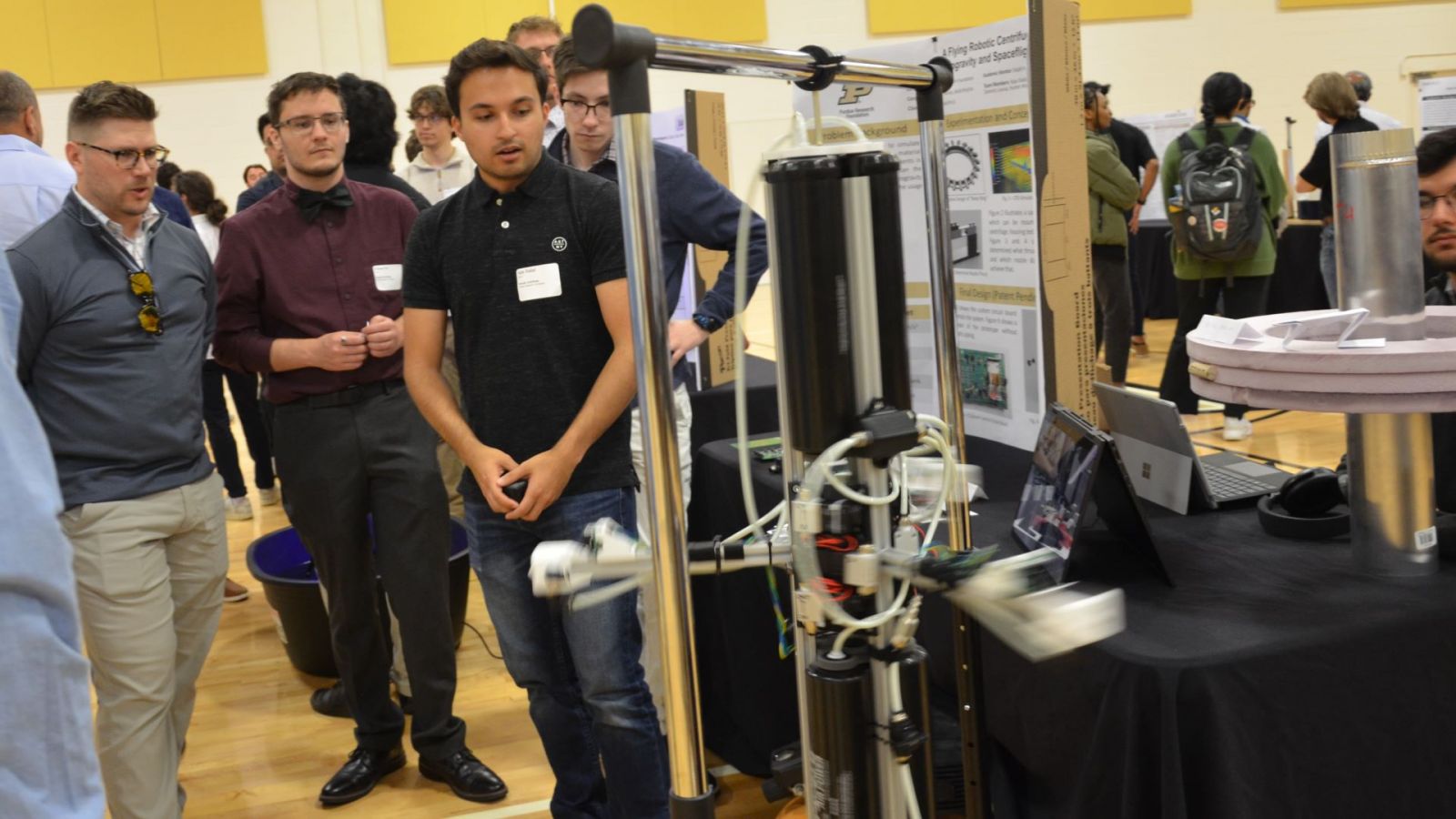

Team 4 was tasked with finding solutions to an especially tricky problem in space industries: gravity simulation. “We know, for instance, that researchers on the International Space Station [ISS] have no way of simulating 1g,” said mechanical engineering technology senior Dominic Lovisa. “1g” indicates that gravitational force in a given location is equal to what it is on Earth.

The team went about creating a centrifuge device which could reliably produce 1g, without the need for flammable fuel sources that would be banned from the temperamental, oxygen-rich environment of the ISS. They built a hydraulics-powered centrifuge, which could allow for heavy metals from an asteroid mining sample to be sorted out as though the sample was being put through the same device on Earth.

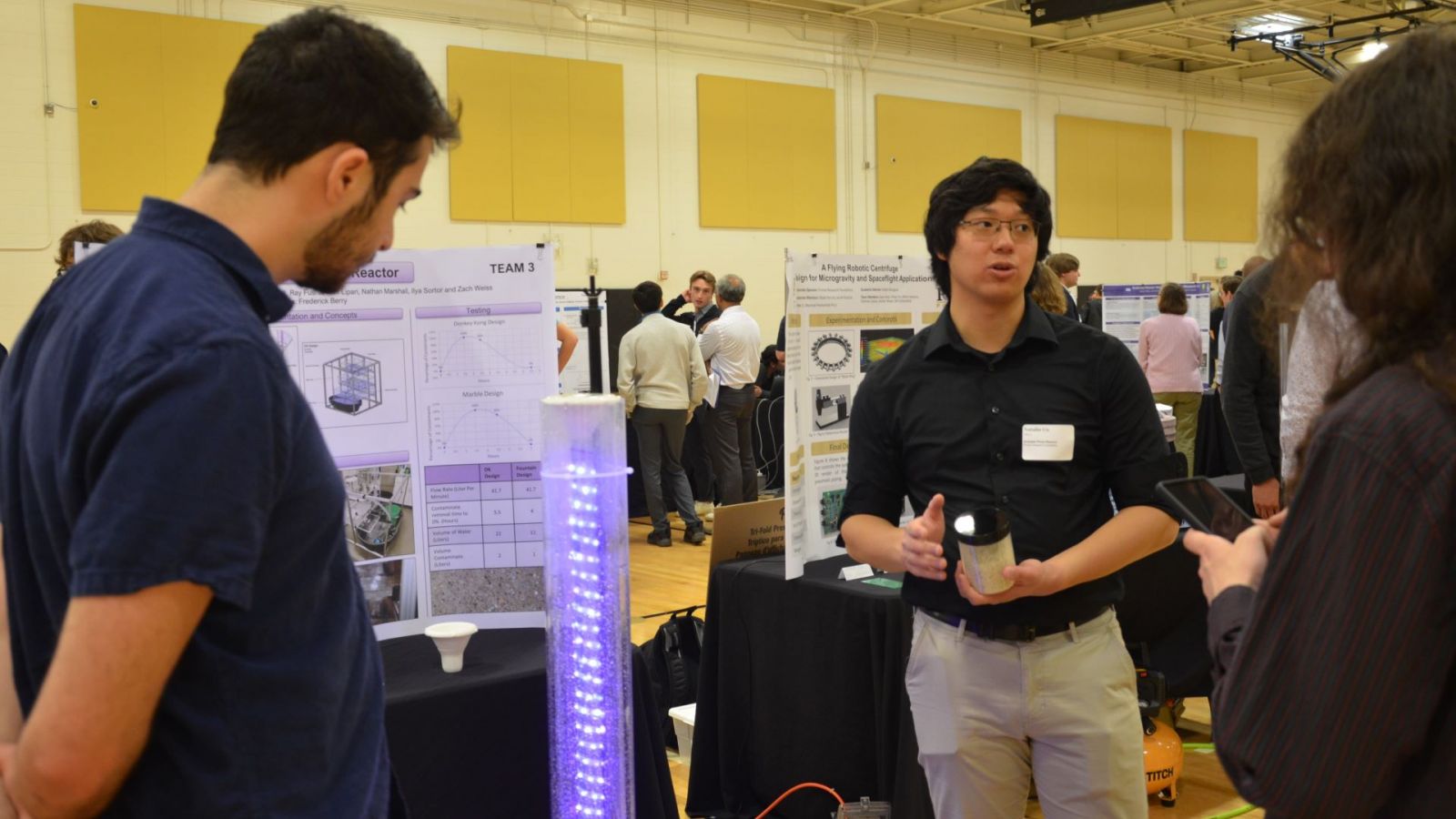

A similarly ingenious device lit up with purple UV lights was on display next to the centrifuge: Team 3’s columnar water-filtration device. This filter removes mass quantities of “forever chemicals” from water.

“This project was all from scratch—[faculty partner] Fred Berry and our sponsor Infineon had confirmed that the background chemistry would work, but we created the whole system from the ground up,” said Drake Farrell from mechanical engineering technology.

“The trick here is to increase the surface area that the water comes into contact with as much as possible, to increase the amount of time that it gets exposed to the UV light within the structure. That meant using custom-made glass beads coated in something called titanium dioxide. Those things provided maximum contact, and then any solids such as the titanium compound still in the water get filtered out as it reaches the bottom of the tube.”

In the aftermath of the Tech Expo, the graduating seniors are no longer seen in labs across campus, where they had previously spent weeks building out their capstones. But once they graduate, many of them will move into jobs that they have already clinched in prior weeks and months.

On the floor of the Expo, students could be heard discussing upcoming roles at companies like Northrop Grumman, RoviSys, Indiana Microelectronics and more.

Additional information

- Tech Expo 2023 hosts student designs, technological solutions for businesses (Purdue Polytechnic newsroom)

- 2024 Tech Expo project and sponsor information

- Purdue Polytechnic’s School of Engineering Technology