Purdue’s learning ecosystem combines fully functional Smart Manufacturing Labs with lessons in high-tech elements of Industry 4.0– such as artificial intelligence, robotics, cloud computing and the Internet of Things.

These labs are more than learning environments —they are incubators for innovation, where students can synthesize the full spectrum of smart manufacturing with hands-on, active problem-solving.

Our Smart Facility Ecosystem

In addition to the over-arching Learning Factory, the synergetic manufacturing system consists of four partner facilities all linked via networks and data streams for real-time analytics. Each facility supplies a unique education element – such as producing sub-assemblies, products, training or analytics – for inclusion in the overall manufacturing process, thereby creating a supply chain for the Learning Factory. These production facilities are being developed in partnership with the Intelligent Manufacturing Advisory Board.

Smart Factory

Smart Factory

Scale model of a smart cyber physical production system (CPPS) for students to design, implement, and develop the full range of Smart Manufacturing competencies

Major Sponsor: Accenture and Microsoft

Smart Foundry

Smart Foundry

Incorporate our sensor-embedded, smart micro-manufacturing facility for metal-casting and small-batch component-making.

Major Sponsor: Caterpillar

Industrial IoT Laboratory

Industrial IoT Laboratory

Connect data with AI across wireless networks for remote monitoring, prototyping and testing of embedded applications.

Major Sponsor: Fortinet

Continuous Process Laboratory

Continuous Process Laboratory

Use IoT to collect real-time data that analyzes databases and develops operational intelligence in manufacturing systems.

Major Sponsor: Endress+Hauser

What Makes This Program Unique?

Leading edge technology-based curriculum

By continuously collaborating with industry thought leaders, we ensure that the latest vision and the newest technologies are integrating into the curriculum. This ensures our students are learning the most relevant skills needed for future success.

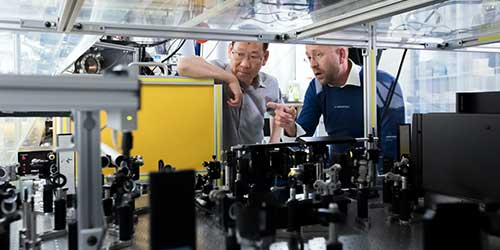

Physical & Virtual Labs

We take direct input from technology and manufacturing leaders to design, build, and refresh our learning facilities. Our goal is to help students learn in physical and virtual representations of the factories of the future, while using the latest industrial-grade equipment, applications, and processes.

Immersive, hands-on experience

We provide our students with immersive hands-on experiences that utilize AI, Machine Learning, Industrial IoT, Mixed Reality, Data Science, Cybersecurity, and more. This will expose our students to real-world manufacturing scenarios to better prepare them to become smart manufacturing leaders of tomorrow.

Our Four-Facility Ecosystem

In addition to the over-arching Learning Factory, the synergetic manufacturing system consists of three partner facilities all linked via networks and data streams for real-time analytics. Each facility supplies a unique education element – such as producing sub-assemblies, products, training or analytics – for inclusion in the overall manufacturing process, thereby creating a supply chain for the Learning Factory.

Smart Factory

Scale model of a smart cyber physical production system (CPPS) for students to design, implement, and develop the full range of Smart Manufacturing competencies

Major Sponsor: Accenture and Microsoft

Smart Foundry

Incorporate our sensor-embedded, smart micro-manufacturing facility for metal-casting and small-batch component-making.

Major Sponsor: Caterpillar

The Industrial IoT Laboratory

Connect data with AI across wireless networks for remote monitoring, prototyping and testing of embedded applications.

Major Sponsor: Fortinet

Continuous Process Laboratory

Use IoT to collect real-time data that analyzes databases and develops operational intelligence in manufacturing systems.

Major Sponsor: Endress+Hauser

Academics

Today’s manufacturers require a new level of innovative graduate who is adept at implementing and optimizing the very latest Industry 4.0 technologies.

Purdue Polytechnic immerses students into Industry 4.0 by creating a connected, real-world manufacturing environment, complete with product and production, that prepares our graduates to lead the rapidly evolving world of manufacturing.

Bachelor of Science Degree in Smart Manufacturing Industrial Informatics

Our Smart Manufacturing Industrial Informatics major bridges traditional and smart manufacturing technologies. Students incorporate cloud computing, industrial and supply chain IoT, enterprise connectivity, simulation and AR, robotics, AI and big data analytics, additive manufacturing and manufacturing cybersecurity.

Dual Master of Science Degree

The Dual Master of Science Degree is a unique offering presenting students with the opportunity to graduate with degrees from both Purdue and Reutlingen University. The program highlights the Industry 4.0 agenda through the utilization of IoT, data, intelligence, and cyber-physical operations in its manufacturing production systems.

Partners

On behalf of the students, faculty and staff of the Purdue Polytechnic Institute’s Smart Learning Factory, thank you to our partners. Our innovation would not be possible without you.