ENGINEERING A SOLUTION FOR…POND SCUM?

What does pond scum have to do with engineering?

That’s the question that ran through Justin Thompson’s mind when a professor suggested that his senior project at Purdue Polytechnic Kokomo address a problem for the Russiaville, Indiana, Park and Tree Board. It seems a community pond had been completely overtaken by algae (aka pond scum), leaving fish breathless, local residents with an eyesore, and Parks & Rec with a potentially expensive, ongoing problem to address.

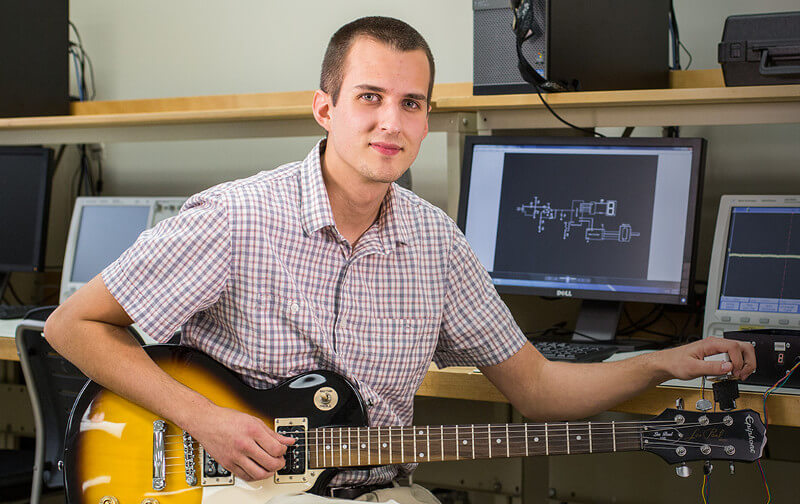

Thompson, who graduated with a degree in engineering technology in May 2016, admits he was a little surprised but accepted the challenge to help find a solution for the algae-choked pond. If there’s one thing the Sharpsville, Indiana, native has learned during his four years at Polytechnic, it’s how to be a problem solver.

“My professors at Purdue Polytechnic don’t just lecture. They keep you learning with hands-on assignments and labs. So when I got this real life project, I jumped in. I knew if I had questions, my faculty advisor was always available,” he said.

The most common way to get rid of algae is to apply chemicals to the pond, a process that must be repeated several times a year. At $1,000 per application, it’s an expensive fix. Plus, chemical herbicides are an increasingly unpopular solution.

Another possible solution is aeration, which reduces pond algae through a variety of processes. They include reducing the amount of time algae is exposed to sunlight needed to grow, reducing the concentration of phosphorus that supports algae blooms, and creating higher dissolved oxygen levels to shift from harmful blue-green algae to less-noxious green algae. The major hurdle with aeration systems is cost. Commercial aerators run upwards of $7,000, which is out of reach for a small town budget. So Thompson set out to design a cheaper pond aerator maintenance system for Russiaville.

There was a small hitch. The pond had no power source. This is where he applied his engineering technology know-how. He developed a battery-operated aerator system, powered by two solar panels, for less than $800. The solar panels generate enough sustainable power to keep the aerator pumping 24/7 even on cloudy days.

While the initial cost savings of his aeration system is impressive, it is a solution with the potential to keep on giving. There are no ongoing costs for labor, energy or chemicals. The electrical components and solar panels have warranties of five and 25 years respectively, so maintenance is minimal. If the solar-powered aeration system proves successful at disrupting harmful algae blooms from growing out of control (testing is ongoing), the Russiaville community will once again have a beautiful pond for all to enjoy.

Thompson believes fighting the battle of pond scum with an engineered solution is a good resume builder. He is confident of landing a job after graduation and credits attending Purdue Polytechnic Kokomo.

“I have learned so much. It’s been a blast!” he said.