Researchers in Purdue Polytechnic and the College of Engineering have developed a patent-pending method to add particles to filament and disperse them evenly through a 3D printer, which will aid industry in manufacturing functional parts.

Researchers in Purdue Polytechnic and the College of Engineering have developed a patent-pending method to add particles to filament and disperse them evenly through a 3D printer, which will aid industry in manufacturing functional parts.

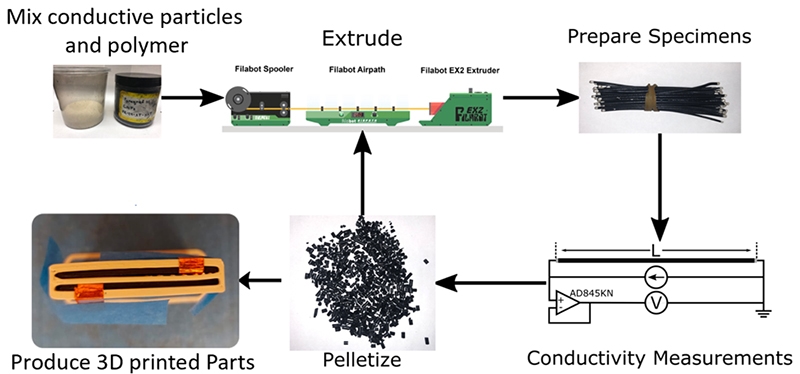

Brittany Newell and Jose Garcia-Bravo, associate professors of engineering technology, along with Tyler Tallman, assistant professor in the School of Aeronautics and Astronautics, and their colleagues created a novel wet-mixing method to introduce electrically conductive particles into filament polymers used in traditional fused deposition modeling, or FDM, 3D printers.

Sensors must be added after the fact to prototype parts made through the traditional 3D printing process. Newell said that foil-type strain gauges, which are the most common strain sensors, are adhered to the surface of traditionally printed parts by an epoxy resin.

“Generally, we apply that strain gauge across the full part or apply it to the top and bottom of the part to get information on overall strain across the part,” Newell said. “However, the middle and internal structures are never monitored since the gauges are glued to the surface.”

The research team’s method allows for the creation of parts that have sensors inside the 3D-printed components themselves. The sensors are too small to be seen without a microscope, a tiny size that allows the printed part to maintain their strength. The team’s wet-mixing method ensures an even distribution of particles throughout the filament. With the sensors dispersed evenly in the filament, manufacturers and researchers can design parts with a wider variety of shapes.

Garcia-Bravo said, “The materials are also tunable, meaning we can adjust the electrical and mechanical properties to optimize the sensor or part for a desired application.”

See the full Purdue Research Park News story by Steve Martin.