A new design for the inner workings of water-cooling towers marks a small step towards increasing the overall efficiency and financial performance of industrial power plants, thanks to Purdue Polytechnic’s Bryan Hubbard.

A new design for the inner workings of water-cooling towers marks a small step towards increasing the overall efficiency and financial performance of industrial power plants, thanks to Purdue Polytechnic’s Bryan Hubbard.

Hubbard, professor of construction management technology and recent recipient of Purdue’s Murphy Award for outstanding undergraduate teaching, was granted the third patent of his career on May 21, 2020.

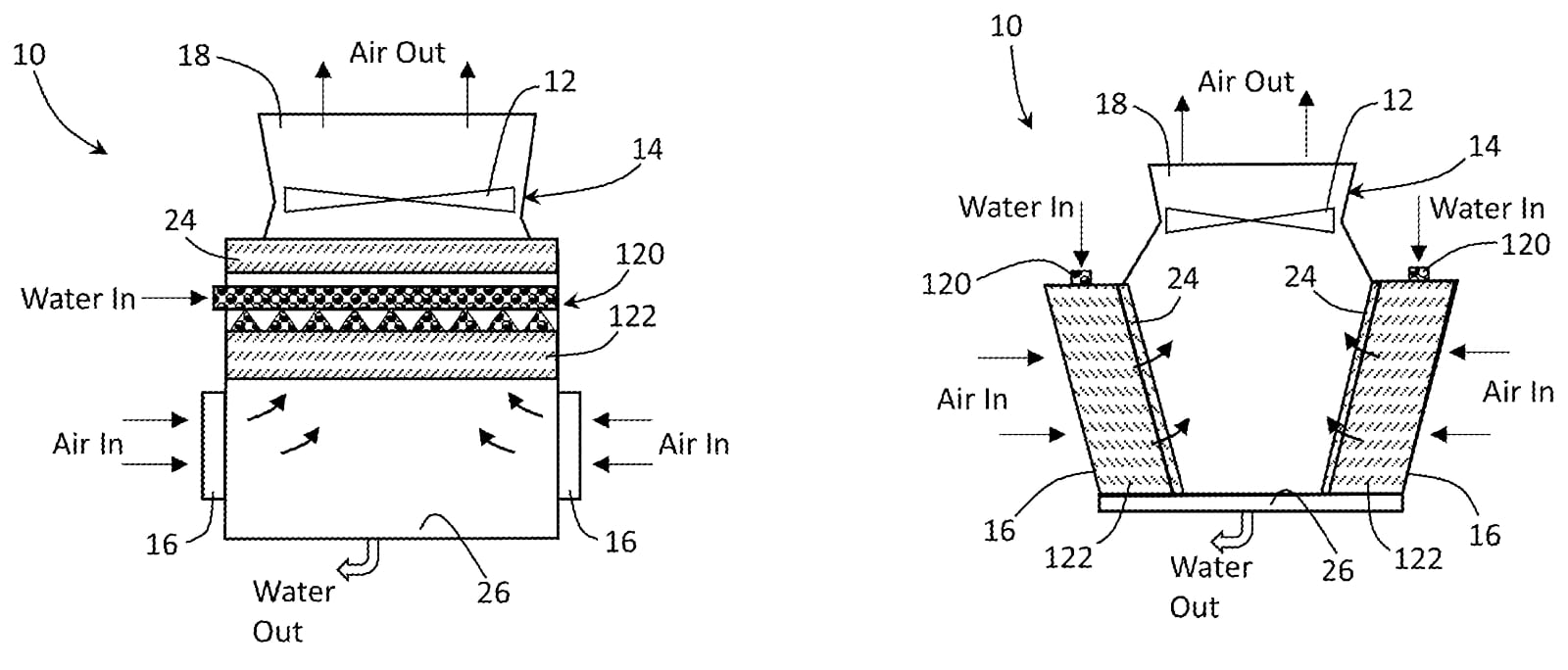

The new technology improves the thermal performance of evaporative water-cooling towers, which are used in many commercial and industrial processes to provide system cooling for power generation and industrial manufacturing. A small but critical cog in the power plant machine, any improvement in heat exchanger performance directly affects the overall efficiency of the system.

Inside the towers, hot water is filtered through small plastic sheets called “film packs,” while underneath, an industrial fan sends up wafts of cool air. This process instigates and speeds up the process of evaporation that would occur naturally.

“It’s just like when you sweat, and wind passes over your skin. You instantly feel cooler,” Hubbard explained.

The proposed concept will enhance water adhesion to the film packs by introducing a differential static electric charge into the plastic. Water will “stick better” to the film packs because the element can have either a negative or positive charge. Gravitation to different sides of the plastic sheets based on electrical charge slows the flow through the film-fill media by spreading the water out and improving the evaporation rates.

Although the new design has yet to be implemented fully into the large-scale industry, the patent suggests financial and environmental benefits, like a reduction in biofouling, for future power plants once efficiency differences exceed five percent.

Since the development of formed plastic film sheets in the 1970s, limited progress has been made in the modern development of industrial cooling towers until now. It is a niche field, Hubbard said, but the uniqueness is what makes developing new technologies so interesting.

“It has great potential and that’s the most exciting thing,” Hubbard said. “You never know what your idea will snowball into.”