A new hands-on lab focused on simulated avionics upgrades could soon be available to students in the School of Aviation and Transportation Technology (SATT).

Avionics are the electronics within an aircraft that provide critical information and controls to pilots, such as flight control systems, fuel systems, radio communications, and navigation systems.

In the aviation industry, avionics sales and maintenance shops are currently experiencing a deficit of qualified workers to provide avionics installation services, but Don Barnes, a SATT clinical assistant professor, has a plan for filling the skill gap.

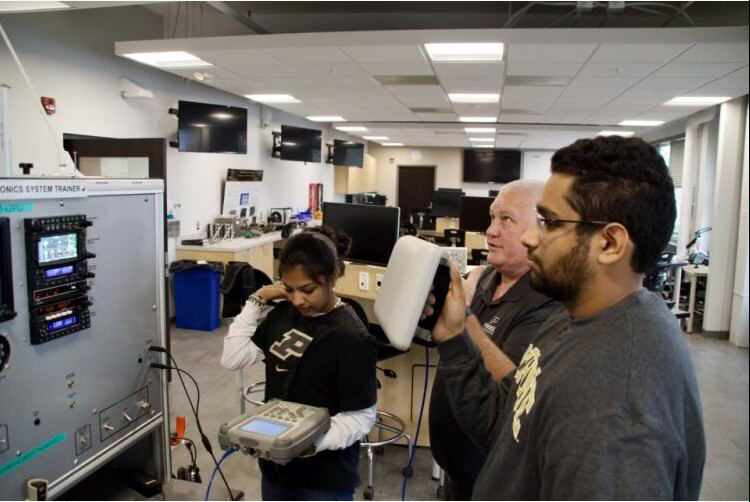

Barnes has been working with Tim Ropp, a SATT clinical professor, and industry partners like Textron Aviation in Indianapolis to develop a more realistic and comprehensive Aeronautical Engineering Technology (AET) lab reflecting evolving technologies, techniques, marketplace needs and AET graduates’ experiences.

The mobile avionics installation trainer being developed will be a central part of the lab. It will challenge students to plan, design, install, and troubleshoot avionics installations while contending with more realistic access and physical space limitations commonly experienced in a real aircraft environment.

Prior to joining Purdue, Barnes worked as an avionics shop lead for Hawker Beechcraft (now Textron Aviation) and also spent 20 years in the Navy as an aviation electrician and flight engineer.

“I learned how to perform modifications and installs in the Navy and as part of on-the-job training at other shops,” Barnes said. “The longer I was in aviation, I began to see that new techs did not possess this skill set, and as a shop lead, I did not always have the time to train them.”

Historically, most technicians entering the workforce have learned how to perform avionics installations during on-the-job training, but the new AET lab will provide a semester of experiential learning. With a comprehensive avionics-related project on their resumes, AET graduates can be better prepared to meet industry needs and gain an advantage in a competitive job market.

“We want to advance from just practice wiring a static schematic board to students visualizing and working a more realistic installation as flown, with students experiencing what it’s like troubleshooting or wiring up a device as it exists in the air or commercial space vehicle itself,” Ropp said.

The new lab will feature a 16-week simulation focused on the modification process, understanding technical data, interpreting drawings and blueprints, and documentation. It will also be aligned with current Federal Aviation Administration regulations and develop specific skills—in this case, skills in aviation, automotive, and aerospace industries.

“With Professor Barnes’s idea for the trainer, students encounter a more realistic workspace with reduced visibility, difficult access—sometimes while laying upside down—and what it takes to achieve absolute reliability and airworthy task work in those conditions,” Ropp said.

By the end of the lab, students should be able to install a new avionics suite or upgrade an analog system to a digital system, such as a Garmin G1000 all-glass avionics suite. At the end of 16 weeks, students will be required to power it up and ensure it operates correctly. If it doesn’t operate correctly, students will need to switch from an “installer” role to a “troubleshooter” role. Avionics troubleshooting is incorporated into all three of Barnes’s classes, with the discrepancies becoming more difficult with each class.

Ropp says the new lab will also progressively incorporate tools like gaming and AI technologies, augmented and mixed reality vision and robotics applications, which they anticipate students will encounter more often as the industry continues to adopt these technologies. This is designed to raise graduates’ competency levels and makes them workforce-ready in aviation and aerospace.

Barnes has developed another avionics lab based on a test he used for applicants to his workshop. That lab became part of the Aircraft Electrical Systems (AT26502) course and teaches students how to repair wires, install components such as terminal lugs and connector contacts, and create wiring harnesses. The new avionics lab in development will be integrated into the Aircraft Electronics (AT44502) course, which is a capstone course for AET majors but is open to other SATT majors as an elective.

Barnes has been modernizing and developing the SATT avionics laboratory experience in phases for the last two years. Major portions of the newest avionics installation trainer will be tested and put into service as early as the fall 2025 semester, depending on acquisition and funding for some of the major electronics needed.

Additional information