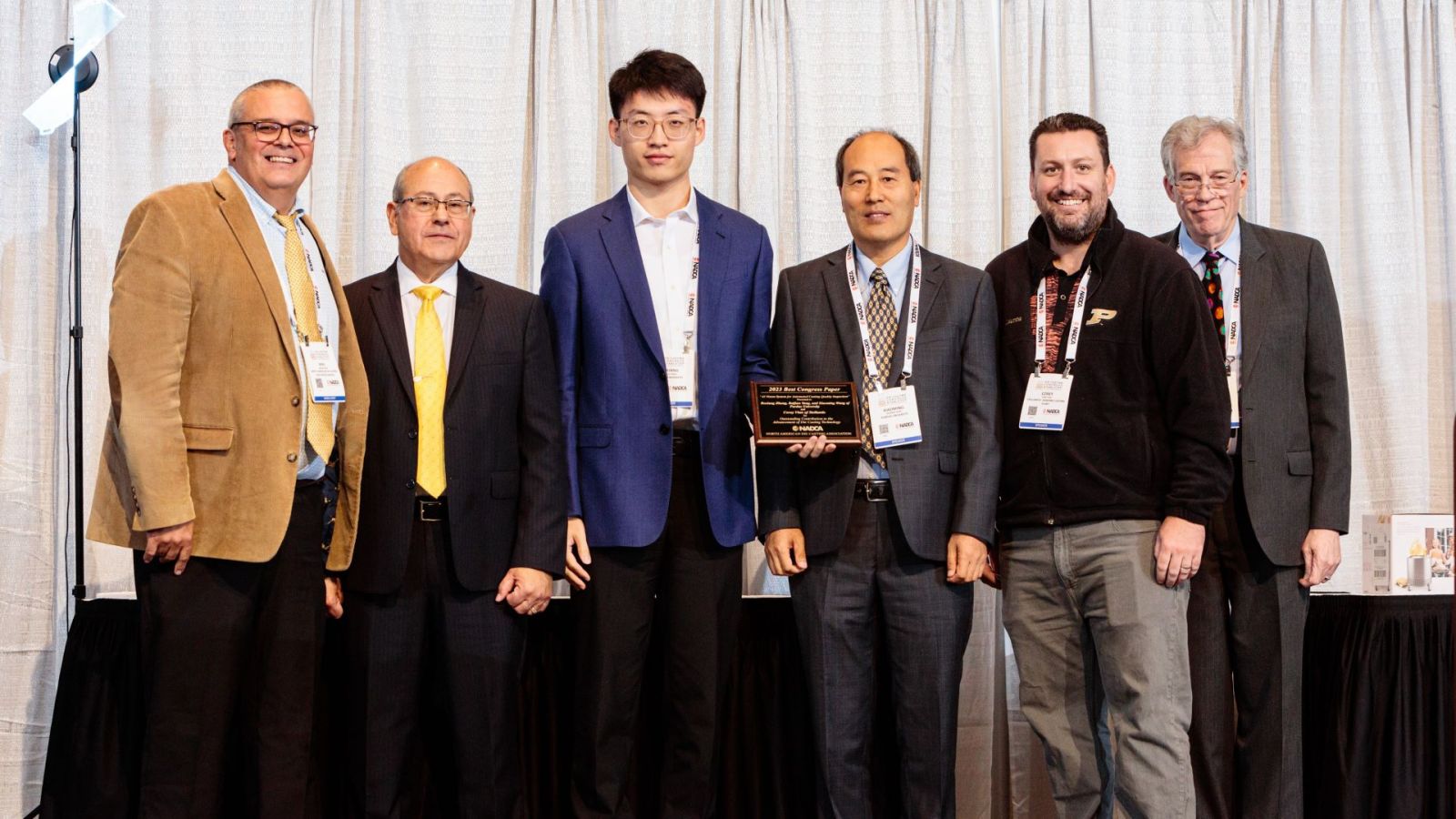

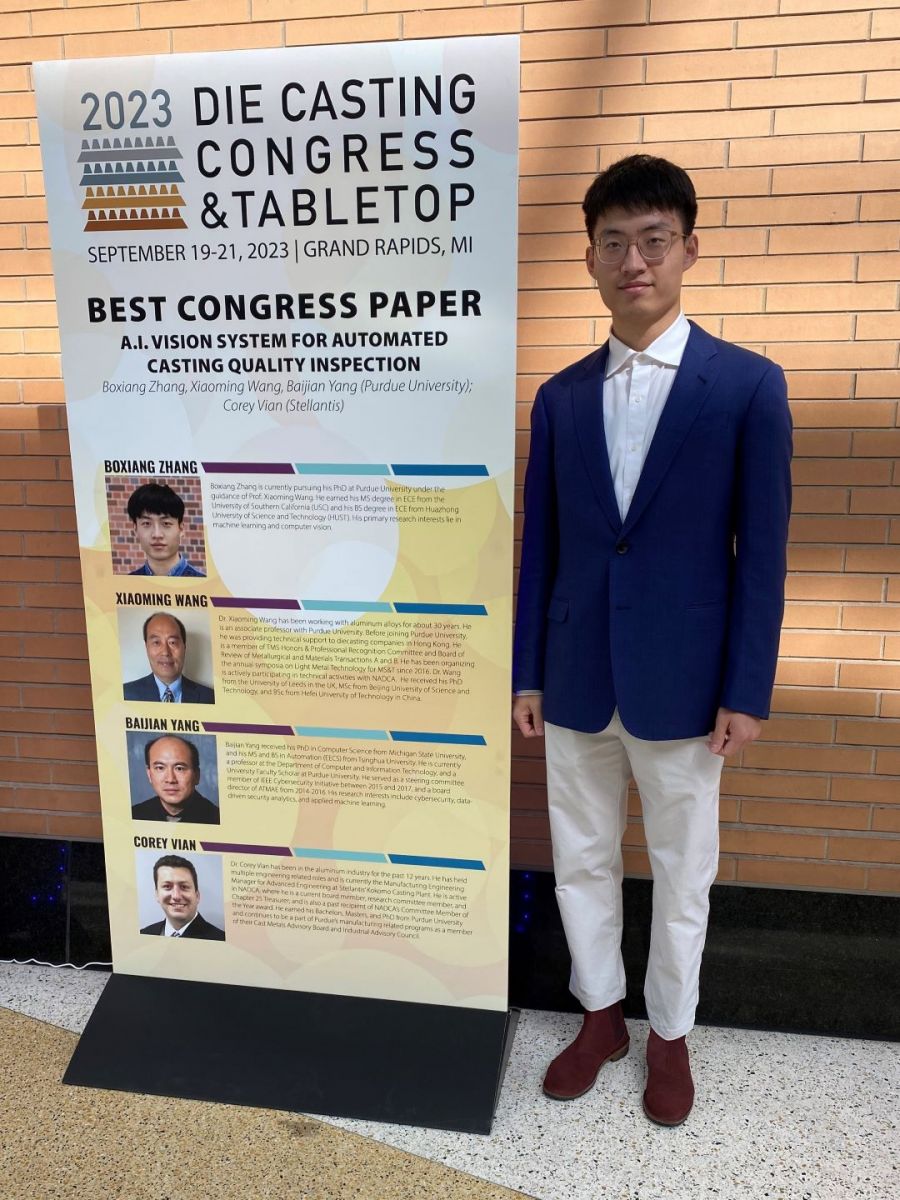

Four authors were awarded the “Best Congress Paper” by the North American Die Casting Association (NADCA) at their annual conference in Grand Rapids, Michigan.

These four authors (Boxiang Zhang, Xiaoming Wang, Baijian “Justin” Yang and Corey Vian) represent various affiliations with Purdue Polytechnic. Zhang is a PhD-level graduate student, working with Wang, an associate professor in engineering technology and his faculty mentor. They were joined in their research by Yang, the recently appointed associate dean for research in the Polytechnic and also a professor in engineering technology.

These three were joined by an industry partner in Vian, a manufacturing engineering manager for Stellantis’ Kokomo location. This location is a die-casting plant, and Vian himself is both an alumnus and a sponsor on behalf of Stellantis for engineering technology’s senior capstone projects at the undergraduate level.

How it works

Altogether, the four-person research team presented their titular work on an “A.I. Vision System for Automated Casting Quality Inspection.” In this case, the research team was concerned with aluminum die-casting. The casting process is one in which molten metal is injected at high pressure into a mold, which is then allowed to cool into a solid shape. The final products have a variety of applications, from the automotive industry to home appliances and many in-between.

At present, quality assurance is difficult during the casting process. At present, workers have to manually inspect products. In their research, the authors showed that manual inspection leads to “a high percentage of scrap and, in worse scenarios, [defective products] being shipped to customers.”

Their solution uses an AI-based vision system to inspect the cast products and determine their quality. This system not only identifies defects but also precisely locates them on the object, logging where they occur even if it has never seen certain defects before. This “Vision Transformer,” using deep neural network-based technology, successfully demonstrated an ability to quickly find mistakes, create a more consistent production process and to save money by reducing scrapped materials.

Advancing a larger body of work

The work from this particular group also provides successive instances of progress among the wider research community within Purdue Polytechnic; during the School of Engineering Technology’s Tech Expo for spring 2023, Zhang, Wang and Vian were all involved in a much earlier stage of this research.

Vian was the client from Stellantis who had tasked undergraduate seniors in engineering technology with developing some form of defect-detection system. Those students designed the physical housing for the AI vision system, including electrical and mechanical components. They then worked with Wang as a faculty mentor. He and Zhang then collaborated to create the AI’s decision-making algorithm regarding defect detection.

The awarded paper from NADCA showcases that research in fruition, presenting the results of the testing that happened during last semester, and taking lessons from that capstone project to further improve on the vision system.

Additional information