Media Kit Resources:

| Attachment | Size |

|---|---|

| 223.77 KB | |

| 226.34 KB | |

| 196.34 KB | |

| 141.01 KB | |

| 118.08 KB | |

| 135.43 KB |

Professors in three Purdue University colleges, including Purdue Polytechnic, are working together to train K-12 teachers to include microelectronics content in their classrooms. It’s part of an initiative by the U.S. Department of Defense to build a domestic semiconductor industry.

The program, SCalable Asymmetric Lifecycle Engagement in K-12 (SCALE K-12), primarily co-funded by the Trusted and Assured Microelectronics program in the Department of Defense and the Indiana Economic Development Corporation, was awarded an additional $2.5 million from the Silicon Crossroads Microelectronics Commons Hub earlier this year to expand its reach to 19,000 students in 12 school districts across Indiana, Illinois, and Michigan.

Tamara Moore, professor of engineering education, is director of the SCALE K-12 program. Purdue Polytechnic’s Greg Strimel, associate professor of technology leadership and innovation, is the program’s deputy director. The SCALE K-12 project team also includes Morgan Hynes, associate professor of engineering education, and Selcen Guzey, professor of science education, as well as other staff and students from Purdue’s College of Engineering, College of Education, and Polytechnic Institute.

The project team is collaborating with faculty at several Midwestern universities: Anne Ottenbreit-Leftwich at Indiana University, Molly Hathaway Goldstein at the University of Illinois, Rick Hill at the University of Detroit Mercy, and Aman Yadav at Michigan State University. The project also partners with the educational organization Regional Opportunities Initiative, located in Bloomington, Indiana.

The SCALE K-12 team hosted more than 70 K-12 teachers for two separate week-long workshops at Purdue in West Lafayette to learn about microelectronics and semiconductors, with the goal of creating new classroom curriculum. Undergraduate and graduate students from Engineering, Education, and the Polytechnic also participated.

We spoke with Strimel about the origins of the SCALE-12 collaboration between the three Purdue colleges and how K-12 teachers benefited from the summer workshops in West Lafayette.

Newsroom: The SCALE K-12 program was launched in 2022 by Tamara Moore and colleagues in Purdue’s School of Engineering Education and the College of Education. How did you join the team?

Greg Strimel: A lot of Tamara Moore’s work and research in Engineering is in the K-12 space. It’s also connected to even larger-scale initiatives around workforce development for the semiconductor/microelectronics industry. I think there was a time when she thought we’ve got to start earlier to build skills and to promote awareness of these career fields, especially with new semiconductor facilities coming in Indiana. So Tamara and her colleagues launched the SCALE K-12 project, which is now in its second year.

The partnership came through working with more technology and engineering teachers in high schools and middle schools, which is an area of focus in the Polytechnic’s technology leadership and innovation (TLI) department. In TLI, we work to prepare future teachers through our Engineering Technology Teacher Education (ETTE) major. As Tamara and Morgan (Engineering Education), along with Selcen Guzey from the College of Education, continued building partnerships, they brought me in to help as they expanded to include more teachers and to bring additional ideas and technologies to the professional development.

Newsroom: We’re talking on day four of a five-day workshop here at Purdue, and there are dozens of teachers here as well as students. What are they working on this week?

Strimel: We have teachers from around Indiana plus a few from Illinois and Michigan. A group of graduate students are here — Engineering Education students, PhD in Technology students and Masters of STEM Education Leadership students. We also have a few undergrads from the ETTE and Electrical Engineering Technology programs here helping out along the way. It’s nice having a mix of students from our different colleges. This week we’re working mainly with middle and high school teachers. We had a week with elementary and middle school teachers last month, too. They’re working to develop new curriculum to bring the concepts related to microelectronics and semiconductors into the classroom. We also provided a lot of opportunities for the teachers to learn about different technologies and educational tools that can help integrate these concepts in engaging and relevant ways.

Newsroom: They’re learning about the semiconductor industry and doing some hands-on projects. What are some of the specific things they’re doing?

Strimel: The first half of this week was a lot of discussion about what the semiconductor industry is like today. But we also talked about some of the tools that we can use in the classroom to help teach about it.

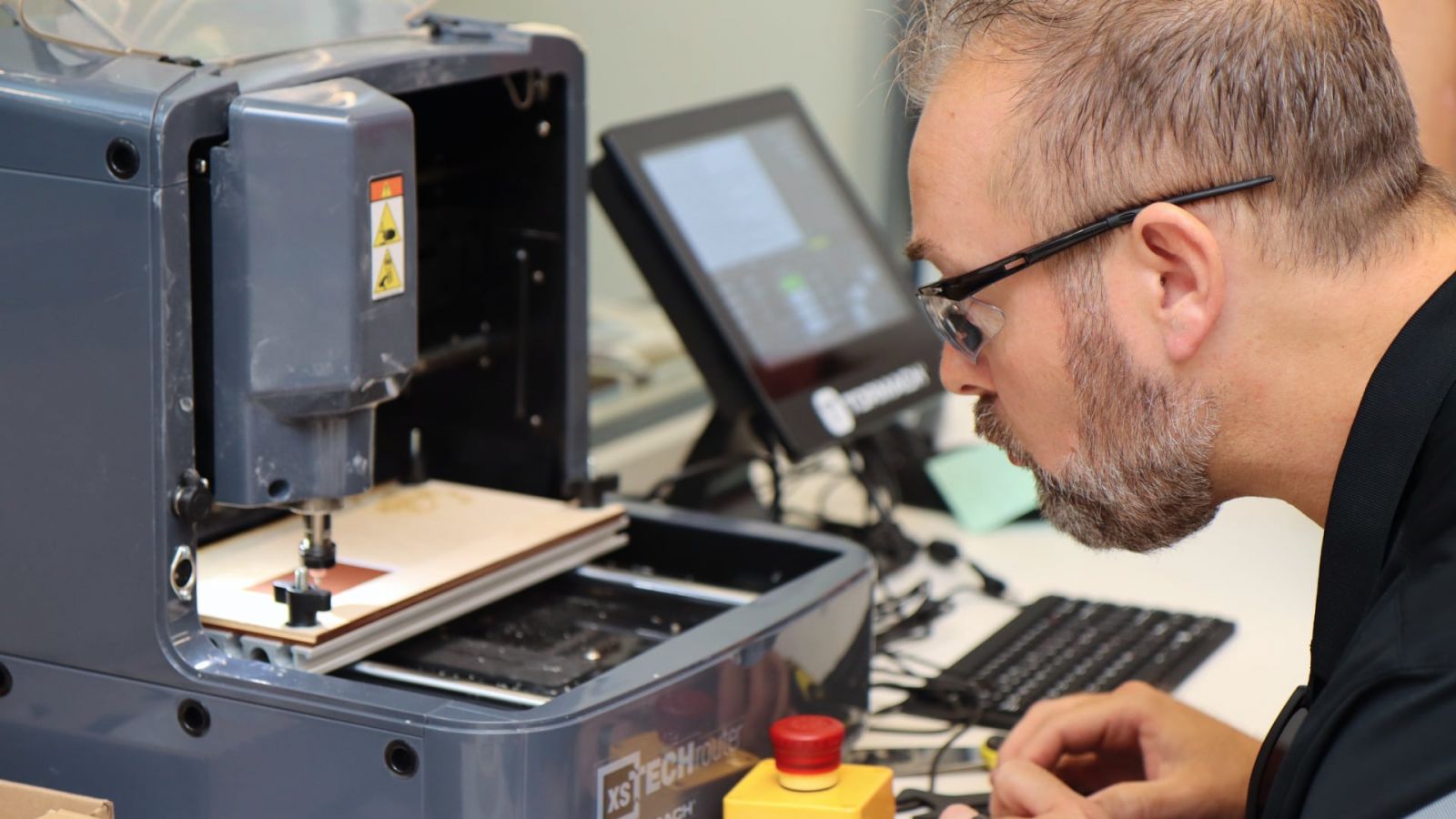

For example, one group of teachers is working on a CNC (computer numerical control) mill, using it for milling out printed circuit boards. With these tools, we can progress from prototyping electronics to making products that are more permanent. They’re actually making a part for a board game, like a digital dice product. They will teach their students how the electronics work, how to design a circuit board and lay out the circuit pathways, and how we use and program microchips to control the electrical components to complete a desired function.

To better understand how a microchip works and how they are made, we’ve done some activities to help them understand how transistors work and how they are made at the microscopic level. We try to scale it down, to see tools like microcontrollers, the Arduino and Microbit, and to understand processes—how the silicon wafers are made into microchips and how the microchips process information in the form of electrical signals, which is the foundation of our electronics today.

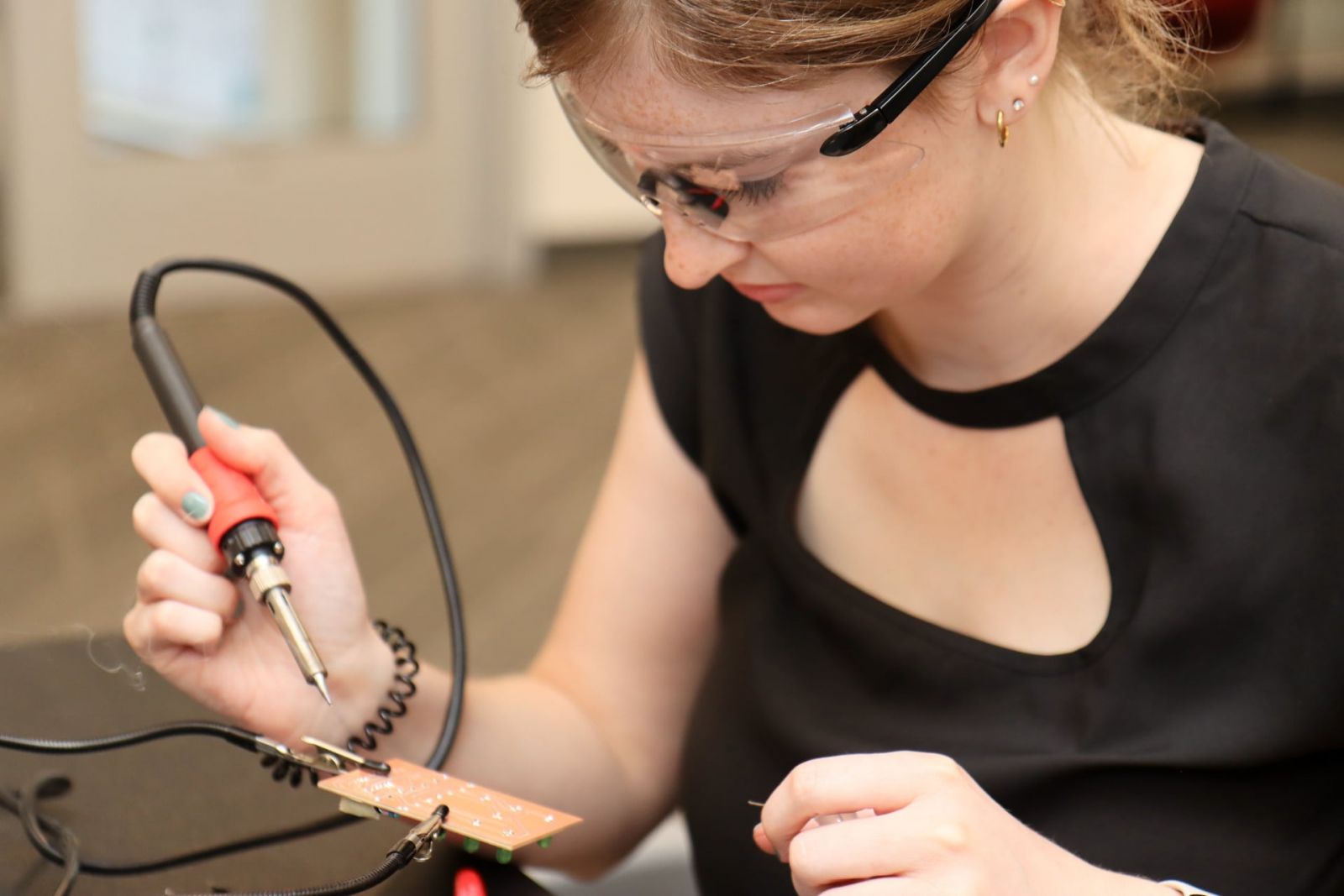

You saw Amiah Clevenger, a junior in Engineering Technology Teacher Education, soldering on a circuit board that we made today. Thanks to support from Brady Barnes, a sophomore in Electrical Engineering Technology, these boards have a little microchip, an integrated circuit, that we programmed—with the chip we put an input in, a button-push for the game, and it will randomly generate a roll of the dice on there.

The cool part is they’re actually making it. They’re not just programming it on the screen or just soldering electronic components together—they’re actually designing the circuit, making the circuit board, and then putting the components together, making sure the microchip is programmed the way they need to complete the desired task. They’re trying to get a lot more into the manufacturing of that type of stuff so they can see how it works.

Newsroom: They plan to take this experience back to their K-12 classrooms to teach some of these projects, right?

Strimel: Yes, it’s to inspire what they can do as they develop curriculum for their schools. It’s going to be piloted in the schools over the next year. And we’ll be working with the teachers not only to help implement it, but also to collect data on what works, what doesn’t—those type of things. So it is an ongoing thing. From there, the curriculum will be refined and basically shared for anyone to use for free on Purdue’s nanoHUB platform.

It’s been fun, especially since they’re not all engineering technology teachers. They’re learning to teach about this industry through their specific subject areas. We have science, English and social studies teachers. So there are many different subjects and concepts they’re looking at—from supply chain aspects to the technical manufacturing side of it. It’s great that we get to bring these concepts into a nice range of subject areas.

Newsroom: That’s incredibly cool! So this collaboration is interdisciplinary at both university and K-12 levels. Why is that important?

Strimel: We’re thinking broadly about all the stuff that’s happening—the recent Purdue CHIPS summit, the partnership with the Department of Defense, the bigger push to get semiconductor manufacturing onshore—and we need to develop expertise for all of it. I’m glad that the Polytechnic gets to work with the College of Engineering, College of Education, and our friends in Illinois and Michigan for this. And it’s fun to work with teachers.

This partnership, and the workshops we’re doing, are all about teaching teachers so that they can teach the next generations—students in K-12 today who will go to college and who might eventually become professionals in the semiconductor industry. We hope students will be interested in seeing where they can go with this, especially since there will be more jobs in Indiana in this field soon.

| Attachment | Size |

|---|---|

| 223.77 KB | |

| 226.34 KB | |

| 196.34 KB | |

| 141.01 KB | |

| 118.08 KB | |

| 135.43 KB |