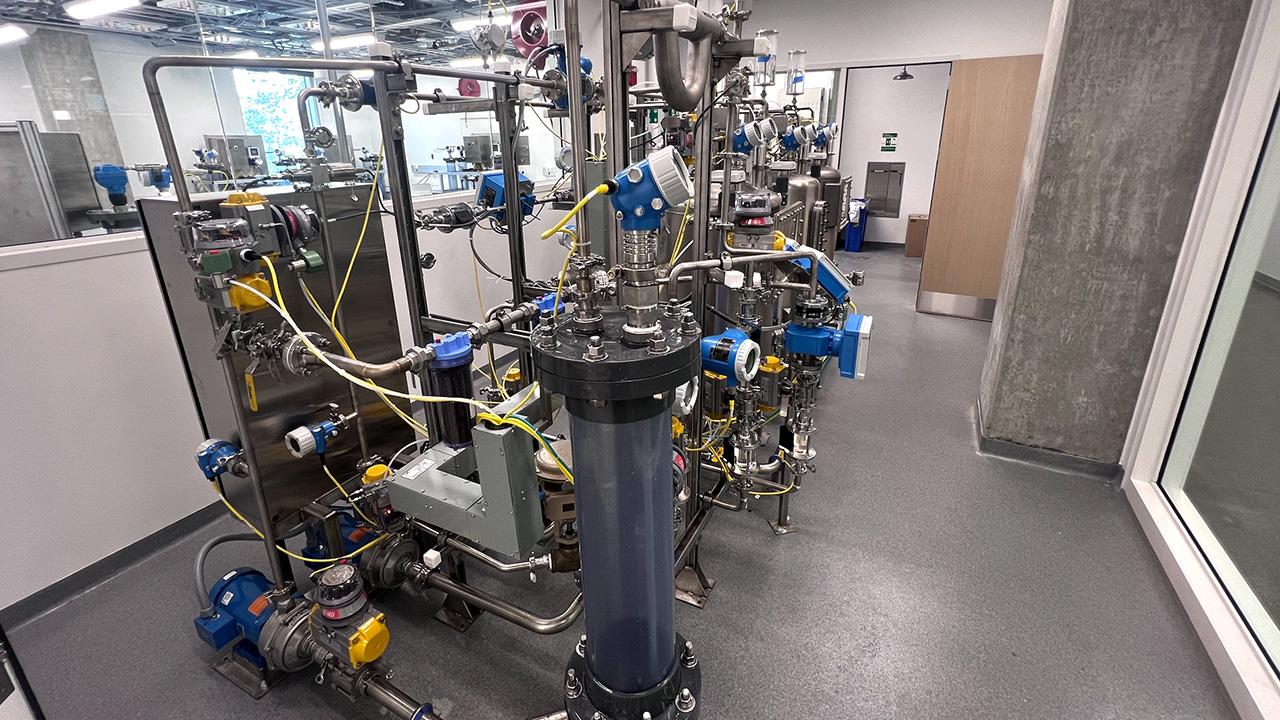

Continuous Process Lab

The Purdue Continuous Process Laboratory is an advanced model of industrial process controls configured in a real-world application.

Educational Application

The lab is designed to immerse students in a variety of engineering concepts regarding measurement, observation and creation of liquid and dry mixtures, pressures, levels, and temperatures in an industry comparable manufacturing environment. It is a mixed-use environment, enabling learning and research related to sensors, data acquisition and process control.

Early in the educational journey, students from multiple degrees within the School of Engineering Technology will be introduced to basic fluid principles within this lab. In the senior level courses, they will assume responsibility, operating, designing, and implementing process improvements in areas including pump performance monitoring, cavitation prediction, quality control and purity monitoring, filter performance, and plausibility of a liquid analysis measurement loop.

The laboratory serves:

- MFET 230 (IIoT Networks & Systems I)

- MFET 350 (Smart Manufacturing Systems Modeling & Simulation)

Available Equipment

- 3 Mixing Chambers

- Fluid Pumps

- Actuators

- Control Valves coupled with Programmable Controllers

- Traditional Industrial Sensors

- Industry 4.0 Wireless Edge Devices - capturing and reporting instantaneous process information.

- Qty: 6 Mobile Process Control Carts