Purdue Polytechnic: A persistent innovator in manufacturing

Purdue Polytechnic has a one-of-a-kind curriculum for students: it is both wide and deep, with a vast range of interdisciplinary courses applicable across STEM, alongside simultaneous options to specialize in the latest industry-relevant technologies.

Purdue Polytechnic, the college for technology, is set to provide Purdue, Indiana, the nation, and the world with the opportunity to persistently pursue technology’s frontiers. Come see how we’re using our skills to bring manufacturing into the 21st century.

Smart Manufacturing

Smart Manufacturing

Industry Partners

Collaboration fuels innovation. At Purdue Polytechnic, our partnerships with industry leaders have been pivotal. They've enriched our facilities, spurred new programs, and broadened our research scope. This synergy has amplified student engagement, upskilled professionals, and driven innovation, firmly positioning Purdue Polytechnic at the cutting edge of manufacturing education and research.

GIANT LEAPS IN MANUFACTURING

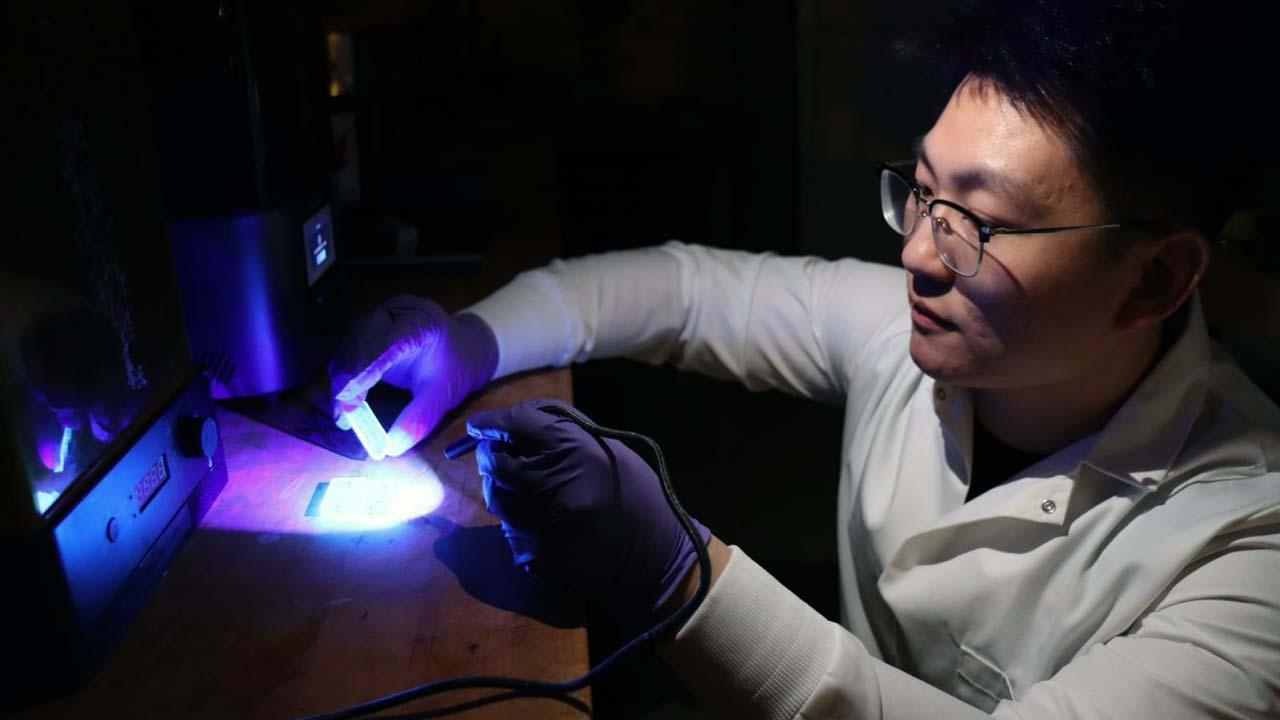

Purdue Polytechnic is at the forefront of groundbreaking research in manufacturing. Our dedicated faculty and student researchers are continually pushing the boundaries to develop technologies, methodologies, and solutions that drive the future of the industry.

Purdue’s Bechtel Innovation Design Center has received a new, high-tech addition to its manufacturing capabilities, thanks to a donation facilitated by an alumnus who…

Vera Tan, a Ph.D. student in Purdue Polytechnic, has received the 1st Best Paper Award at the 13th CIRP Global Web Conference (CIRPe 2025), a major international…

Purdue University and Rittal and Eplan, sister companies and global leaders in industrial and electrical engineering solutions and automation, have announced a major…

When national leaders gathered on Capitol Hill on July 23rd to call for strong federal investment in science and technology, Purdue Polytechnic was there to represent…

Our Smart Facility Ecosystem

New innovations are constantly emerging in manufacturing. This will only accelerate as Purdue leads the charge in re-shoring semiconductor production. The workforce of America’s semiconductor industry will need to be trained to the highest standards—and Purdue Polytechnic has everything they need.

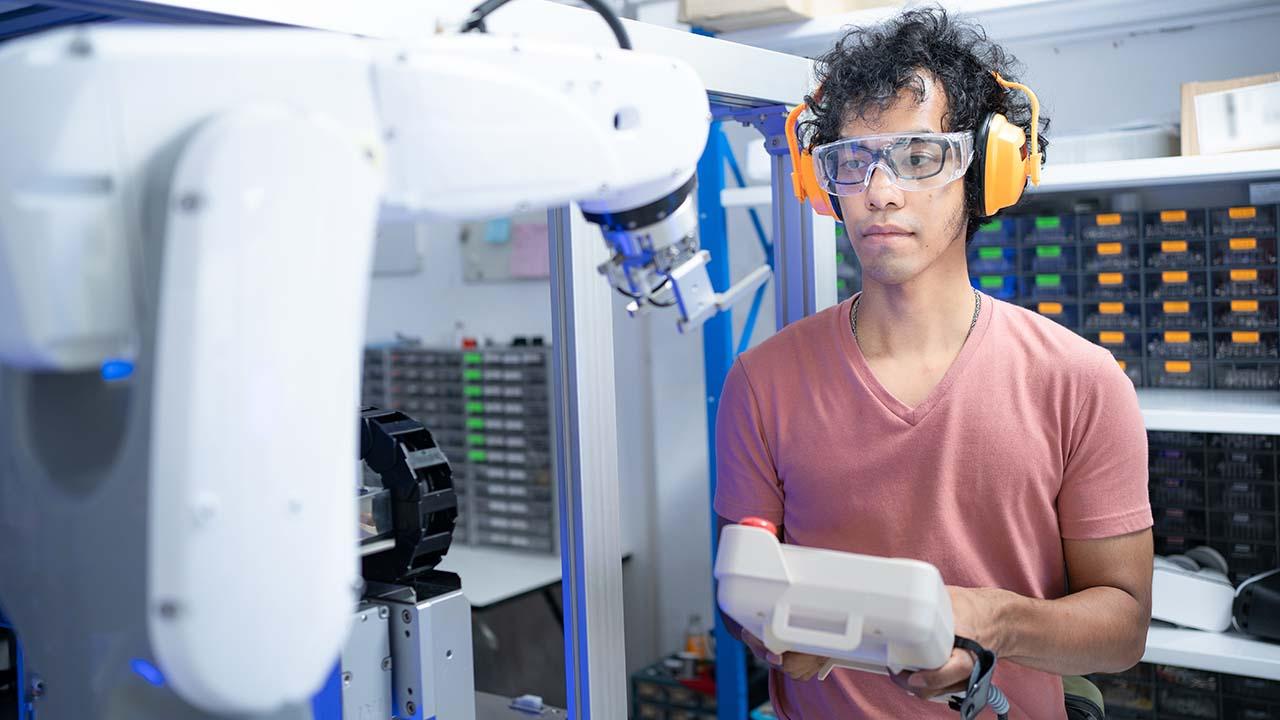

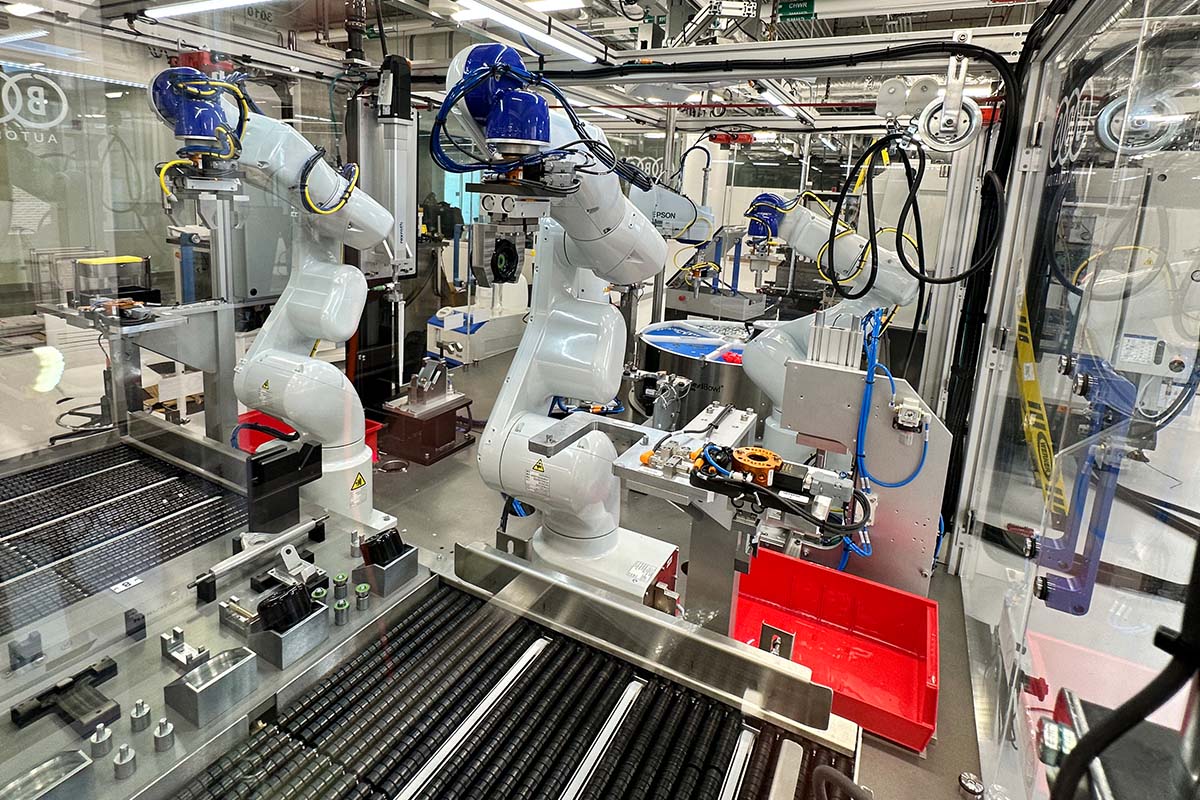

We've established the nation’s largest Smart Manufacturing ecosystem in Dudley and Lambertus. Here, Polytechnic students don't merely simulate a high-tech, digitally-enhanced manufacturing environment. They build real products and generate authentic data, mirroring how top manufacturers gather their insights.

These state-of-the-art facilities provide students and researchers with the tools they need to explore, innovate, and excel. Taking insight from a variety of European partner institutions, Purdue Polytechnic's manufacturing facilities are the only one of their kind in the nation.

Smart Manufacturing

Smart Manufacturing

Manufacturing Majors

At Purdue Polytechnic, our commitment to manufacturing excellence extends far and wide. With over 30 courses specializing in various facets of manufacturing—from smart manufacturing data management to manufacturing integration—our offerings are not just confined to manufacturing-centric majors. They are seamlessly embedded into a wide spectrum of our Polytechnic programs, ensuring students across disciplines are equipped with the manufacturing prowess needed in today's industry. Our curriculum is meticulously crafted to empower students with the knowledge and skills essential for driving innovation in modern-day manufacturing.