Realizing the Digital Enterprise

News

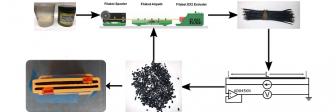

Purdue Polytechnic’s Jose Garcia-Bravo, Robert Nawrocki, Brittany Newell and Jinsheng Fan have combined 3D printing and electric poling into a single process known as the EPAM method. This innovation saves time and money, which has the potential to revolutionize the manufacturing of products with smart sensors like robots and medical devices.

An interdisciplinary team of Purdue Polytechnic researchers received National Science Foundation (NSF) funding to study how teams of humans and robots will work together at construction sites. The team hopes the NSF grant will serve as the foundation for years of collaborative research to improve the efficiency and scalability of human-robot teams in constrained and complex construction workplaces.

Purdue Polytechnic’s Brittany Newell and Jose Garcia-Bravo and their colleagues created a novel wet-mixing method that allows for embedding sensors within the structure of 3D-printed parts. Their patent-pending method will aid industry in manufacturing functional parts.

Undergraduate and graduate students in Purdue University’s Polytechnic Institute presented posters summarizing their 2021-2022 research projects. Student research projects affiliated with the Polytechnic’s Realizing the Digital Enterprise research impact area are summarized here. (Part 2 of 2.)

Undergraduate and graduate students in Purdue University’s Polytechnic Institute presented posters summarizing their 2021-2022 research projects. Student research projects affiliated with the Polytechnic’s Realizing the Digital Enterprise research impact area are summarized here. (Part 1 of 2.)

Purdue Polytechnic faculty in the “Realizing the Digital Enterprise” research impact area are working to pair technological capability and social responsibility, creating successful cyber–physical experiences.