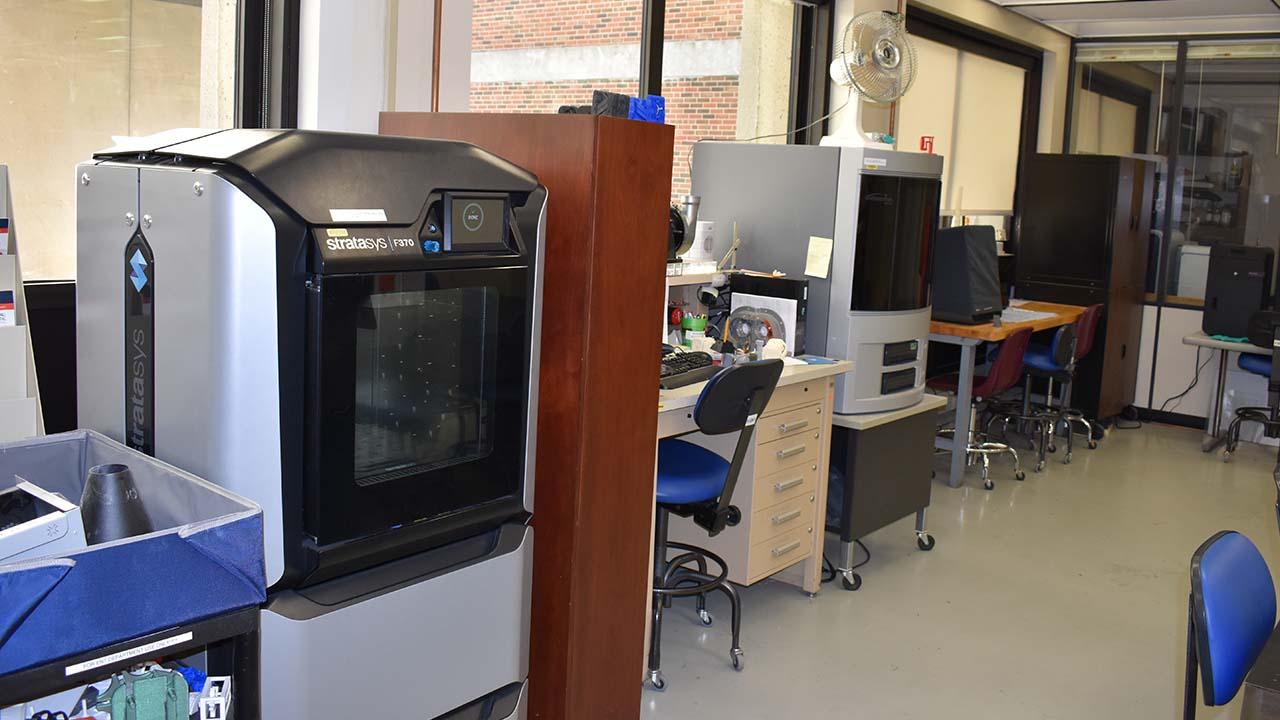

Applied Technologies Laboratory

The Applied Technologies Laboratory offers Mechanical Engineering Technology students a versatile, hands-on environment to explore and master core principles in hydraulics, mechanics, materials testing, thermodynamics, and rapid prototyping. This lab is equipped with training systems for fluid power, materials testing machines, thermal analysis tools, and 3D printers, enabling students to engage with a wide spectrum of engineering technologies in a single location. Here, students apply theoretical principles to practical tasks, from building and testing hydraulic circuits to conducting material strength assessments and thermal efficiency studies. The lab’s 3D printing and rapid prototyping capabilities also allow students to design, fabricate, and test models, fostering skills in iterative design and product development. By integrating these diverse technologies into an experiential learning environment, the Applied Technologies Laboratory prepares students with the technical skills and problem-solving abilities essential for thriving in modern, multifaceted engineering fields.

This laboratory serves:

- MET 20400 - Production Drawing

- MET 21100 - Applied Strength of Materials

- MET 22000 - Heat and Power

- MET 23000 - Fluid Power

- MET 32000 - Applied Thermodynamics

- MET 32800 - CAD/CAM for Mechanical Design Drafting

- MET 34800 - Engineering Materials

- MET 41400 - Projects in Mechanical Design

Lab Equipment:

- PA Hilton tube heat exchanger

- Thermodyne Type 2200 hot plates

- Benchtop variable speed open loop wind tunnel

- Sperry Vickers modular fluid power trainers

- PASCO ME-8236 materials testing machine

- Scott Engineering Scientific Corporation polariscope

- SpectraQuest machinery fault simulator

- Turbine Technologies LTD Rankine Cycler steam turbine power system

- Carrier modular packaged HVAC training unit

- Testing Machines Inc. 43-01 impact tester

- Gunt Hamburg solid-pendulum impact tester

- Leco MX400 metallographic sample mounting press

- Leco SS200 variable-speed grinder

- Buehler LTD Handimet grinder

- Motic AE2000MET inverted metallurgical microscope

- Rockwell and Brinell hardness testers

- Stratasys F370 FDM 3D printer

- Formlabs Form 3+ desktop resin 3D printer

- Formlabs wash and cure post processing station

- Lisa Sinterit SLS 3D printer

- Sinterit powder sieve