Purdue Polytechnic's School of Engineering Technology has initiated a new software partnership that allows students to simulate complex manufacturing processes without the need for expensive physical trial and error.

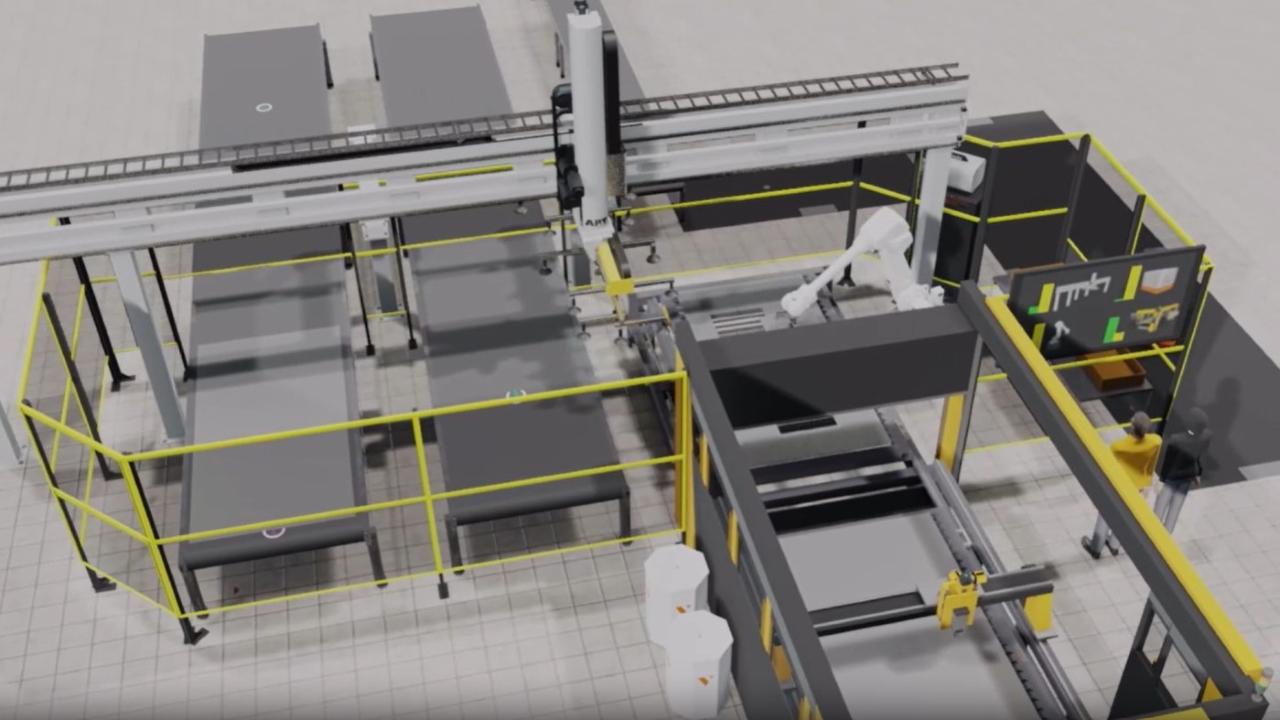

The collaboration is with Visual Components, a leading developer of 3D manufacturing simulation software. Through this partnership, students in the school's innovation engine courses for seniors are working to create a digital twin-a virtual replica-of the Smart Learning Factory located in Dudley and Lambertus Halls.

James Condron, professor of practice in engineering technology, explained that the software allows students to test tooling and machinery configurations digitally before ever bringing the configurations to physical equipment.

“What it's doing is very, very useful,” Condron said. “That digital equivalent is something that you can teach in manufacturing as well, so that students can actually have practical exposure to it from the first year, to be able to design and have a process for making technical parts.”

One of the primary benefits of the Visual Components platform is its extensive library of pre-configured machines. Harit Vyas, a student on the innovation engine design team, noted that the software already includes digital models for the specific equipment used in the Polytechnic's labs.

“It has connectors for all the machines that we have in the laboratory,” Vyas said. “For example, the UR10 robot that we have, you just have to send a direct connector for that and you can export code to it.”

This capability allows students to program robotic movements and assembly lines in a virtual environment and then export that code directly to the physical machines, streamlining the production process.

For the university, the partnership also represents a significant cost advantage. Condron noted that licensing for industrial-grade simulation software can be prohibitively expensive across the industry, making an academic partnership essential for providing students with access to top-tier tools.

The project is ongoing, with current innovation engine teams laying the groundwork for future cohorts to build upon. Condron envisions a multi-semester progression where students eventually integrate multiple “cooperative stations” into a fully automated, digitally simulated system.

“We do monthly meetings with Visual Components just to give them a checkpoint on what progress we have made,” Vyas said. “If we have any issues with the software, they're very receptive about it. Really talking with them directly has been a huge benefit to this team.”

Additional information